Living Radical Polymerization by the RAFT Process – A Third Update

Graeme Moad A B , Ezio Rizzardo A and San H. Thang AA CSIRO Materials Science and Engineering, Bag 10, Clayton South, Vic. 3169, Australia.

B Corresponding author. Email: graeme.moad@csiro.au

Graeme Moad obtained his B.Sc. (Hons, First Class) and Ph.D. in organic free radical chemistry from Adelaide University. He joined CSIRO in 1979 and is currently a chief research scientist. Dr Moad is author/co-author of over 150 publications, co-inventor of 33 patent families and co-author of the book The Chemistry of Radical Polymerization. His research interests lie in the fields of polymer design and synthesis. In recognition of his work, Dr Moad was recently awarded the RACI’s Battaerd-Jordan Polymer Medal. Dr Moad is a titular member of the IUPAC Polymer Division and a Fellow of the RACI and the Australian Academy of Science. |

Ezio Rizzardo FRACI, FTSE, FAA, FRS received his Ph.D. from the University of Sydney in 1969 and joined CSIRO in 1976 after post-doctoral research at Rice University, RIMAC, and the Australian National University. His CSIRO research has focused on developing methods for controlling free radical polymerization. He is co-author of some 200 journal papers with over 14,000 citations, and co-inventor on 44 worldwide patents. He has received a number of awards including the RACI Australian Polymer Medal, the CSIRO Chairman’s Gold Medal and an Australian Government Centenary Medal. In 2011, he was the co-recipient of the Prime Minister’s Prize for Science. |

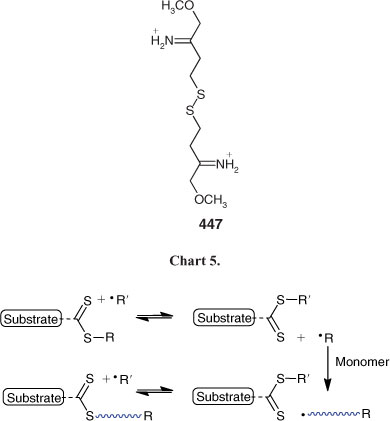

San H. Thang completed his Ph.D. in chemistry at Griffith University in 1987. Currently, he is a chief research scientist at CSIRO Materials Science and Engineering, and an adjunct professor at Monash University. San’s research focuses on the interface between biology and polymer chemistry. He has published over 100 papers which have to date received over 10,000 citations. He is responsible for several key inventions in the area of controlled/living radical polymerization; significantly, he is a co-inventor of the RAFT process. San is a Fellow of the Australian Academy of Technological Science and Engineering, and a Fellow of the Royal Australian Chemical Institute. |

Australian Journal of Chemistry 65(8) 985-1076 https://doi.org/10.1071/CH12295

Submitted: 19 June 2012 Accepted: 25 July 2012 Published: 7 September 2012

Abstract

This paper provides a third update to the review of reversible deactivation radical polymerization (RDRP) achieved with thiocarbonylthio compounds (ZC(=S)SR) by a mechanism of reversible addition-fragmentation chain transfer (RAFT) that was published in June 2005 (Aust. J. Chem. 2005, 58, 379). The first update was published in November 2006 (Aust. J. Chem. 2006, 59, 669) and the second in December 2009 (Aust. J. Chem. 2009, 62, 1402). This review cites over 700 publications that appeared during the period mid 2009 to early 2012 covering various aspects of RAFT polymerization which include reagent synthesis and properties, kinetics and mechanism of polymerization, novel polymer syntheses, and a diverse range of applications. This period has witnessed further significant developments, particularly in the areas of novel RAFT agents, techniques for end-group transformation, the production of micro/nanoparticles and modified surfaces, and biopolymer conjugates both for therapeutic and diagnostic applications.

Introduction

Radical polymerization is one of the most widely used processes for the commercial production of high molar mass polymers.[1,2] The emergence of techniques for implementing reversible deactivation radical polymerization (RDRP), which serve to impart living characteristics to the process, has provided a new set of tools for polymer chemists that allow control over the polymerization process whilst retaining much of the versatility of conventional radical polymerization. It is no longer a formidable task to apply radical polymerization to the synthesis of blocks, stars, or other polymers of complex architecture. New materials with the potential of revolutionizing a large part of the polymer industry continue to appear. The polymerization techniques that are receiving greatest attention are nitroxide-mediated polymerization (NMP),[3–6] atom transfer radical polymerization (ATRP),[7–11] and reversible addition–fragmentation chain transfer (RAFT).

The controversy over the use of the terms ‘living’ and ‘controlled’ in describing processes for radical polymerizations such as ATRP, NMP, or RAFT was addressed by the International Union of Pure and Applied Chemistry (IUPAC).[12] IUPAC recommends that the term living polymerization be confined to refer to ‘a chain polymerization from which irreversible chain transfer and irreversible chain termination (deactivation) are absent’. This effectively precludes use of the adjective ‘living’ in describing processes based on radical polymerization.[13] While it is acceptable to describe radical polymerizations such as ATRP, NMP, or RAFT as controlled polymerization, it is also regarded as inappropriate to use ‘controlled’ in an exclusive sense to define a particular class of polymerization processes since the word has an established, much broader, usage. Use of the terms ‘controlled living’, ‘controlled/living’, ‘pseudo-living’, and ‘quasi-living’ in this context is also discouraged. An IUPAC task group has recommended the use of a new term (controlled) reversible deactivation radical polymerization (RDRP) to describe polymerizations, such as ATRP, NMP or RAFT, which entail equilibria between active and dormant propagating species.[14] This term is not intended to have any connotations as to the fraction of living chains that might be present in a particular polymerization process and does not imply any particular degree of control.

It remains acceptable to use the term ‘living radical polymerization’ to describe a hypothetical process in which termination is indeed absent. It is in this context that we use ‘living radical polymerization’ in the title of this review and the previous articles of this series. We do not intend to imply that termination is absent from any of the polymerizations described herein. Many systems do display the observable characteristics normally associated with living polymerizations and in a few cases, termination, while undeniably present, is not detectable using current techniques.

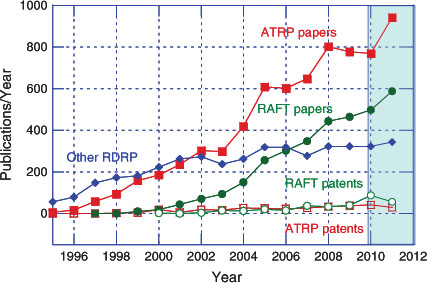

The increasing importance of RAFT polymerization is illustrated by Fig. 1 which shows the cumulative citations for our first communication on RAFT with thiocarbonylthio compounds,[15] the first RAFT patent,[16] and our previous reviews in the Australian Journal of Chemistry.[17–19] Of course, not all papers on RAFT polymerization cite these sources, nor are all of the papers citing these documents directly relevant to RAFT polymerization. Fig. 2 shows that the remarkable growth in publication of papers covering the various forms of RDRP has continued unabated. The total number of papers that relate to ‘RAFT polymerization’ has increased significantly since mid 2009 with more than 1500 papers being published and approximately one-third of papers on RDRP now pertain to the concept ‘RAFT polymerization’.

|

|

This review is primarily intended to cover the literature on RAFT Polymerization that has appeared since publication of the update published in the Australian Journal of Chemistry in late 2009.[19] We also refer to some earlier papers that were not included in that or the earlier reviews. Work cited in the previous reviews[17–19] is only mentioned again where it is necessary to put the more recent work in context.

The last two years has seen the publication of further general reviews detailing the RAFT process, which include general reviews on RAFT polymerization.[20–25] Reviews devoted to specific areas include those on the kinetics and mechanism of RAFT polymerization,[26,27] RAFT agent design and synthesis,[28] the use of RAFT to probe the kinetics of radical polymerization,[29] microwave-assisted RAFT polymerization,[30,31] RAFT polymerization in microemulsion,[32] end-group removal/transformation,[33–36] the use of RAFT in organic synthesis,[37] the combined use of RAFT polymerization and click chemistry,[38] the synthesis of star polymers and other complex architectures,[39–42] the synergistic use of RAFT polymerization and ATRP,[43,44] the synthesis of self assembling and/or stimuli-responsive polymers,[45–47] and the use of RAFT-synthesized polymers in green chemistry,[48] polymer nanocomposites,[49–51] drug delivery and bioapplications,[41,46,47,52–60] and applications in cosmetics[61] and optoelectronics.[62] The process is also given substantial coverage in most recent reviews that, in part, relate to polymer synthesis, living or controlled polymerization or novel architectures. Some of those that include significant mention of RAFT polymerization include reviews on RDRP,[63] mechanism and reagent design,[11,64,65] click chemistry,[66–72] synthesis of telechelics,[73] the polymerization of carbazole-containing monomers,[74] N-vinyl-1,2,3-triazoles,[75] N-vinyl heterocycles,[76] fluoro-monomers,[77] and glycomonomers,[78–80] synthesis of metallopolymers,[81] conjugated block copolymers,[82] dye-functionalized polymers,[83] stimuli-responsive polymers,[84,85] complex architectures,[86,87] polyolefin blocks,[88] biopolymer–polymer conjugates and bioapplications,[59,89–93] polysaccharide modification,[94,95] polymerization in heterogeneous media,[96,97] microwave-assisted polymerization,[65,98,99] industrial prospects for RDRP,[100,101] and applications in the cosmetics industry.[102]

Mechanism of RAFT

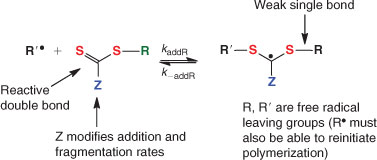

The key feature of the mechanism of RAFT polymerization with thiocarbonylthio compounds, as proposed in our first communication on the subject,[15] is the sequence of addition–fragmentation equilibria shown in Scheme 1. Initiation and radical–radical termination occur as in conventional radical polymerization. In the early stages of the polymerization, addition of a propagating radical (Pn•) to the thiocarbonylthio compound [RSC(Z)=S (1)] followed by fragmentation of the intermediate radical (2) provides a polymeric thiocarbonylthio compound [PnS(Z)C=S (3)] and a new radical (R•). Reaction of this radical (R•) with monomer forms a new propagating radical (Pm•). Rapid equilibrium between the active propagating radicals (Pn• and Pm•) and the dormant polymeric thiocarbonylthio compounds (3) by way of the intermediate 4 provides equal probability for all chains to grow and allows for the production of low dispersity polymers. When the polymerization is complete (or stopped), most of chains are dormant [i.e. PnS(Z)C=S (3)], which possess the thiocarbonylthio end-group, and can be isolated as stable materials.

|

The reactions associated with RAFT equilibria shown in Scheme 1 are in addition to those (i.e. initiation, propagation, irreversible transfer, and termination) that occur during conventional radical polymerization. In an ideal RAFT process, the RAFT agent should behave as an ideal transfer agent. Thus, as is the case with radical polymerization with conventional chain transfer, the kinetics of RAFT polymerization should not be directly affected by the presence of the RAFT agent beyond those affects attributable to the different molar mass and molar mass distribution of the reacting species. Radical–radical termination is not directly suppressed by the RAFT process. Living characteristics are imparted only when the molar mass of the polymer formed is substantially lower than that which would be formed under the same conditions but in the absence of a RAFT agent and is such that the number of polymer molecules with RAFT agent-derived ends far exceeds the number formed as a consequence of termination. Many RAFT polymerizations stray from this ideal.

The initialization process (consumption of the initial RAFT agent) in RAFT polymerization has been studied by 1H NMR spectroscopy for NVP† with a series of xanthates which differ in the ‘R’ group.[103] The selectivity of initialization (and the transfer constant of the RAFT agent) was found to depend strongly on the ‘R’ group. A selective initialization is one in which there is substantial conversion to a single unit adduct before any significant formation of two or higher unit adducts occurs. Xanthates 215, 216, 222 > 224–229 provided (Table 9) selective initialization and were suitable for controlling NVP polymerization with some limitations. Xanthate 221 (R = phenylethyl), which gave a long induction period, and 223 (R = t-butyl), which showed poor selectivity, were not recommended for use with NVP.

|

|

|

|

|

|

|

|

|

RAFT Transfer Constants

The efficiency of the RAFT process is determined by the values of two transfer coefficients, Ctr (= ktr/kp) and C–tr (= k–tr/k–β). The rate coefficient for chain transfer (ktr) for a RAFT agent is given by the Eqn 1. The value of ktr depends on the rate of addition of the propagating radical (Pn•) to the RAFT agent and a partition coefficient (φ) which describes the partitioning of intermediate radical (2) between starting materials and products – refer to Scheme 1:

The transfer agent-derived radical (R•) is also partitioned between adding to monomer and reacting with the macro-RAFT agent (3). We therefore define a rate coefficient associated with this reaction (k–tr) as shown in Eqn 2.

Knowledge of the partition coefficients φ and φβ (note φβ = 1 – φ) and C–tr is important for an understanding of RAFT agent activity. The high reactivity of RAFT agents towards radical addition means that C–tr is seldom zero. Transfer coefficients measured by methods which include an assumption that C–tr is zero or that kβ is zero will typically underestimate Ctr. These values should be called apparent transfer coefficients Ctrapp. In some cases, values of Ctr may be higher than Ctrapp by several orders of magnitude.[104,105] A dependence of Ctrapp on the RAFT agent concentration and/or on monomer conversion is one indication that the reverse reaction is important. The spread in literature values for Ctrapp may be attributed to this effect. Note that the situation is simplified for the case of macro-RAFT agents in homopolymerization where, notwithstanding the effects of chain length, the forward and reverse reactions are the same (Ctr = C–tr) and the partition coefficient φ should be 0.5.

For less active RAFT agents (Ctr ≤ 1), transfer coefficients for RAFT agents may be determined with reasonable accuracy by the usual methods (e.g. the Mayo method). Experimental values of kinetic parameters associated with the RAFT process (addition rate constants (kadd), fragmentation (kβ, k–add) rate constants, and forward (Ctr = ktr/kp), reverse (C–tr = k–tr/ki) and apparent transfer coefficients (Ctrapp)) that have appeared in the literature since, or which were omitted from, our previous review[19] are collected in Table 1.

Gao and Zhu[106] have provided a new analytical expression for estimating values of Ctr of macro-RAFT agents from knowledge of the dispersity and the monomer conversion.

RAFT Equilibrium Constants

The properties of RAFT agents are also often discussed in terms of the value of the equilibrium constants (K = kadd/k–add) associated with radical addition to a thiocarbonylthio compound.[26] Rates of addition are typically high (kadd ~106–108 M–1 s–1). Thus a high equilibrium constant generally implies a low fragmentation rate for the radical adduct and an increased likelihood for retardation and/or side reaction involving this species. In a given RAFT polymerization, there are several equilibrium constants that should be considered.

-

KP (= kaddP/k–addP) associated with the main equilibrium.

-

K (= kadd/k–add) and Kβ = (k–β/kβ) associated with the pre-equilibrium.

-

KR (= kaddR/k–addR) associated with the reaction of the expelled radical with the initial RAFT agent (Scheme 2). Note this is the same as KP when R• is a propagating radical.

|

There are other equilibrium constants to consider if penultimate group effects and the chain length dependence of the various rate constants are considered. Recent reports of values for rate constants for addition (kadd) and fragmentation (k–add) and of the equilibrium constant K are collected in Table 2.

Theoretical calculations have been performed to rationalize the reactivity of RAFT agents and predict RAFT equilibrium and rate constants.[26,116–118] Rodríguez-Sanchez et al.[116,119] used DFT methods and frontier molecular orbital theory to predict the dependence of reactivity of RAFT agents on the ‘R’[119] and ‘Z’ substituents.[116] However, the results are at odds both with experiment and previous theoretical calculations using ab initio or other methods. For example, they[116] suggest an order of reactivity decreasing in the series where Z is Ph > PhCH2 > dithiocarbamate > xanthate > trithiocarbonate. DFT methods were also applied to calculate the molecular structure of dibenzyl trithiocarbonate, and predict its infrared (IR) and ultraviolet (UV-vis) spectra, dipole moment, electrical polarizability, and static first hyperpolarizability.[120]

Lin and Coote[117] indicate that ab initio methods should provide good (within an order of magnitude) prediction of the RAFT equilibrium constant (Keq) and have used these method to estimate that between trithiocarbonate 84 and a (model) poly(MA) propagating radical. Lin and Coote[121] also found that Keq was strongly chain length dependent.

Mechanisms for Retardation

Although the basic mechanism shown in Scheme 1 is generally not disputed, debate continues on the detailed kinetics of the RAFT process, the rapidity with which the various equilibria are established, and what side reactions might occur to complicate the process in specific circumstances.[26,122] In particular the mechanism(s) for retardation in RAFT polymerization mediated by, in particular, dithiobenzoate RAFT agents continue to attract significant interest. The incompatibilities of two mechanistic schemes, namely the slow fragmentation model and the intermediate radical termination model were highlighted in a ‘dilemma paper’ by a IUPAC task group in 2006.[126] The slow fragmentation model points to high concentrations of the intermediate radicals 2 and 4, which are not seen by EPR. The intermediate radical termination model suggests the formation of star polymer byproducts formed by self reaction of 4 or by reaction of 4 with propagating species Pn•, which are not observed in the product in the predicted amounts.

Klumpermann and Heuts[26] reexamined the previously reported calculations of Coote and co-workers and experimental determinations of rate parameters associated with RAFT polymerization using dithiobenzoate agents. They concluded that while the then available data did not allow model discrimination between the schemes, the apparent incompatibility of the models, while significant, was less than suggested in some papers. They,[26] and more recently, Junkers[27] have pointed out the need for more reliable measurements of kinetic parameters to fully resolve the situation.

It has been pointed out that chromatography and molecular weight distributions should distinguish between the slow fragmentation and intermediate radical termination models.[127]

Two theories have been put forward to explain the absence of the star polymer by-products expected if the intermediate radical termination model applies that was mentioned in the previous update. These involve the occurrence of (a) a missing step termination or (b) short chain termination.[128] Ting et al.[129] have attempted to answer the question of whether cross-termination (between 4 and Pn•) might involve short radicals only. They[129] compared the rates of polymerization when a macro-azo-initiator (5) and a polystyrene macro-RAFT agent (6) were used in a RAFT polymerization of styrene (St) (this system should involve no short chain radicals) to the situation where cumyl dithiobenzoate (11) was the RAFT agent and azoisobutyronitrile (AIBN) was used as initiator. Other permutations were also examined. While little retardation was observed when the combination of 5 and 6 (Chart 1) was used, neither was retardation observed with 11 as RAFT agent and AIBN as initiator for higher monomer conversions (>40 %). The latter finding is inconsistent with the short chain termination model of Konkolewicz et al.[128]

|

In very recent work, Meiser and Buback[130] isolated a missing-step product from the reaction of 2-cyanoprop-2-yl radicals with 2-cyanoprop-2-yl dithiobenzoate (12) thereby confirming the viability of this mechanism.

Chernikova et al.[118] used an EPR spin trapping method to measure addition and fragmentation rate constants for the reaction between a t-butyl radical and t-butyl dithiobenzoate (38). Their data analysis indicates a high value for K of ~108 M–1 (20°C). Meiser and Buback[123] used an EPR single pulse method to determine addition and fragmentation rate constants for the reaction between 2-cyanoprop-2-yl radicals radical and 2-cyanoprop-2-yl dithiobenzoate (12). Their analysis indicates a low value for K of ~101 M–1 (60°C). As pointed out by Junkers et al.[131] the more than six orders of magnitude difference in K for these two systems appears surprising. It should, however, be pointed out that significantly different K values for the t-butyl and 2-cyanoprop-2-yl systems might be anticipated since it was already known that 12 and 38 have very different activity as RAFT agents. For example in MMA polymerization (60°C) the values of Ctr for 12 is ~25, and that for 38 should differ little from the value of Ctrapp 0.03;[105] a difference of 103. This, however, can only be attributed in part to a difference in kadd, it is also determined by the partition coefficient φ and the relative rates of fragmentation (k–add) with the two RAFT agents. Chernikova et al.[118] determined kadd to be ~106 M–1 s–1. In their analysis, Meiser and Buback[123] assumed kadd to be ~106 M–1 s–1. It seems unlikely (even allowing for a temperature effect) that the kadd should be the same for the two radicals.

Moad et al. used 13C NMR spectroscopy to follow the initiation of St polymerization with AIBN-α-13C and with cumyl (11), 2-cyanoprop-2-yl (15), and benzyl dithiobenzoates (54) and with cyanoisopropyl dodecyl trithiocarbonate (95).[132] It was found that:

-

Rates of polymerization with dithiobenzoate RAFT agents are strongly dependent on ‘R’ and increase in the series where R is cumyl (11) < 2-cyanoprop-2-yl (15) < benzyl (54).

-

The RAFT agent does not affect the efficiency of AIBN initiation. The rate of formation of St adducts was the same for all RAFT agents.

-

The ketenimine by-product from AIBN is converted into a stable by-product in the presence of RAFT agent. This side reaction will cause some apparent retardation since the ketenimine would normally revert to 2-cyanoprop-2-yl radicals.

-

Some evidence for the missing step termination was observed with benzyl dithiobenzoate (54) as RAFT agent was observed but not with other dithiobenzoates (11 or 15).

Suzuki et al.[133] measured rates of dithiobenzoate-mediated St polymerization in bulk and in miniemulsion. They reported that the significantly higher rates for miniemulsion polymerization could not be simulated with the slow-fragmentation model, but could be adequately understood using the intermediate termination model assuming a relatively high fragmentation rate coefficient and a high rate coefficient for termination between the intermediate radical and a propagating radical.

Some comment should also be made on apparent rate constants for intermediate radical termination in solution. In the studies mentioned above, Chernikova et al.[118] determined kt (intermediate radical termination) to be 6.5 × 102 M–1 s–1 (20°C). Meiser et al.[122] estimated kt (intermediate radical termination) as 0.25 kt (BA polymerization, 60°C).

In RAFT polymerization of St with trithiocarbonate 95, Houshyar et al.[109] found that kt (intermediate radical termination) must be <106 M–1 s–1 (it could be zero). Brown et al.[134] studied RAFT polymerization of St with a dithiocarbamate 254 which contains a potentially florescent carbazole chromophore to aid the detection of star products from intermediate radical termination; no stars were detected.

Further analysis is beyond the scope of this update. Suffice to say that this section does not yet have a conclusion. The mechanisms for retardation in RAFT polymerization, in systems where this is found, is not yet fully resolved.

Macromonomer RAFT Polymerization

Historically, the first RAFT process used to provide living characteristics to radical polymerization was that involving so-called macromonomers (7, 8, Scheme 3).[135–137] Macromonomer RAFT polymerization has been reviewed within larger reviews on catalytic chain transfer (CCT).[138,139] Similarities between the chemistry of RAFT polymerization and that seen in formation and reaction of acrylate mid chain radicals were highlighted in a recent publication.[140]

|

A MAA macromonomer prepared by catalytic chain transfer was used to prepare poly(MAA)-b-poly(BA) which was used as a reactive surfactant in emulsion polymerization of poly(MMA-co-BA-co-MAA).[141] Two papers have appeared providing a comparison of block copolymers synthesized by macromonomer RAFT polymerization with polymers of similar overall composition but synthesized by group transfer polymerization (GTP).[142,143] The copolymers synthesized by GTP had substantially better dispersity (Đ = 1.28) and a more homogeneous composition than those synthesized by macromonomer RAFT (Đ = 1.7) and their superior performance in coatings applications was considered to be a consequence of this.

RAFT-Related Processes

Cobalt-Mediated Polymerization

Polymerizations of VAc and similar monomers mediated by cobalt complexes are proposed to involve a RAFT-like mechanism called associative–degenerative chain transfer (DT) or a reversible coupling mechanism, analogous to that of NMP, called organometallic radical polymerization (OMRP).[144] The relative importance of these mechanisms depend on the specific complex, the reaction conditions, and the monomers. A recent study by Kumar et al.[145] indicates that both the DT and OMRP mechanisms operate simultaneously in the case of VAc polymerization mediated by Co(tmhd)2 (9) (Chart 2).

|

Control in BA polymerization or BA/VAc copolymerization was achieved with use of an alkylcobalt(iii)(acac)2 adduct.[146] Block copolymers of poly(VAc)-b-poly(VPv) or poly(VAc)-b-poly(VBz) were achieved by sequential monomer addition.[147] Poly(VAc) formed by cobalt-mediated polymerization with Co(acac)2 (10) (Chart 2) has been transformed to a polymer with a dithiobenzoate end-group to be used in RAFT polymerization of MAMs.[148]

Polymerization Mediated by Organotellurium, Organobismuthine, and Organostibine Reagents

The mechanism and application of radical polymerization mediated by organotellurium (TERP), organobismuthine, and organostibine compounds has been reviewed.[149,150] Recent papers have described the use of TERP in surfactant-free emulsion polymerization of BA[151] and St,[152,153] the preparation of polymer monoliths based on crosslinked poly(Am),[154] the use of poly(NIPAm)-b-poly(NVP) for solubilization of C60,[155] the use of heteroatom–metal exchange reactions in end-group transformation of polymers (poly(BA), poly(MMA), poly(HEMA), poly(NIPAm)) in organostibine or organobismuth-mediated polymerization[156] and the use of organostibine-mediated polymerization in St/MMA copolymerization.[157]

The end-groups of methacrylic polymers (poly(BA), poly(MMA), poly(HEMA), poly(MAN)) formed by TERP or organostibine-mediated polymerization can be eliminated to form macromonomers in high yield through reaction with (2,2,6,6-tetramethylpiperidinyl-1-oxy (TEMPO) (and formation of an alkoxyamine intermediate) or the addition–fragmentation chain transfer agent, ethyl 2-[(tributylstannyl)methyl]acrylate.[158]

Choice of RAFT Agents

The range of thiocarbonylthio RAFT agents (ZC(=S)SR, 1) continues to expand. The factors which influence choice of RAFT agent for a particular polymerization has been presented in various reviews.[17–19,28,137] The effectiveness of the RAFT agent depends on the monomer being polymerized and is determined by the properties of the free radical leaving group R and the group Z which can be chosen to activate or deactivate the thiocarbonyl double bond of the RAFT agent (1) and modify the stability of the intermediate radicals (2) and (4). For effective RAFT polymerization (Scheme 1, Fig. 3):

|

-

The initial RAFT agents (1) and the polymer RAFT agent (3) should have a reactive C=S double bond (high kadd).

-

The intermediate radicals (2) and (4) should fragment rapidly (high kβ, weak S–R bond in intermediate) and give no side reactions.

-

The intermediate (2) should partition in favour of products (kβ ≥ k–add).

-

The expelled radicals (R•) must efficiently re-initiate polymerization (ki > kp).

A summary of ‘new’ RAFT agents and polymerizations in which they and pre-existing RAFT agents have been applied is provided in Tables 3–14. These tables include some RAFT agent/monomer combinations which provide poorer molar mass control and/or Đ > 1.4. Generally this is indicated by the monomer appearing in parentheses. They are included because they help provide understanding of the mechanism and the construction of guidelines for the choice of RAFT agent. In some cases, poor control may reflect an inappropriate choice of RAFT agent for the monomer or unsuitable reaction conditions. In the tables, the RAFT agents generally appear in order of decreasing homolytic leaving group ability of R. Within a class (e.g. with R = tertiary cyanoalkyl), they generally appear in order of increasing complexity of R. Similarly monomers appear in order of decreasing homolytic leaving group ability of the propagating species (i.e. MAMs > LAMs and methacrylates > methacrylamides > styrenics > acrylates > acrylamides > vinyl monomers).

|

|

|

|

|

Several RAFT agents including dithiobenzoates, 12 and 18, the trithiocarbonates, 89, 95, 98, 123, and 171, and the dithiocarbamate, 258, are now commercially available from Sigma–Aldrich[20] or Strem Chemicals.[21] Lubrizol have announced the availability of trithiocarbonate 125 in metric ton quantities.[159,160]

Dithioesters

RAFT polymerizations making use of dithioester RAFT agents are shown in Tables 3–5. Tertiary dithiobenzoates (11–35; Table 3) continue to be popular RAFT agents particularly for synthesizing polymers based on 1,1-disubsituted monomers (namely, methacrylates (e.g. MMA) or methacrylamides (e.g. HPMAm). The corresponding trithiocarbonates (92–120; Table 7) and aromatic and more active forms of the switchable dithiocarbamates (275-H+, 276-H+; Table 13) are less active but also suitable for controlling the polymerization of these monomers. The aromatic dithioesters are more sensitive to nucleophilic attack and more prone to hydrolysis, for example, when employed in aqueous media. They are also more reactive in end-group transformation/removal reactions post RAFT polymerization.

Trithiocarbonates

RAFT polymerizations making use of trithiocarbonate RAFT agents are shown in Tables 6–8. Two classes of trithiocarbonate RAFT agents are distinguished. Symmetrical trithiocarbonates (Table 6) that have two good homolytic leaving groups and non-symmetrical trithiocarbonates (Table 7) that have one good homolytic leaving group and a poor leaving group such as primary alkyl or aryl.[108] The Z-connected bis-trithiocarbonates shown in Table 8 also have two good homolytic leaving groups.

With symmetrical trithiocarbonates having two good homolytic leaving groups, the trithiocarbonate group usually remains in the centre of the polymer structure. However, the major product from the symmetrical trithiocarbonate 81 in MMA polymerization was the mono-macro-RAFT agent.[320] This outcome is attributed to the substantially better leaving group ability of the MMA propagating radical v. the monomeric analogue.

Xanthates (Dithiocarbonates)

RAFT polymerization making use of xanthate (or dithiocarbonate) RAFT agents are shown in Tables 9 and 10. Xanthate RAFT agents are the most popular for controlling the polymerization of vinyl esters (e.g. VAc) and vinyl amides (e.g. NVP).

Dithiocarbamates and Switchable RAFT Agents

RAFT polymerization making use of dithiocarbamate RAFT agents are shown in Tables 11–13. Cyanomethyl N-methyl-N-phenyldithiocarbamate (258) is commercially available from Aldrich[20] and Strem.[21] In recent work, it has been used for controlling the polymerization of VAc[366] and VC.[529]

Further details of RAFT polymerization using ‘switchable’ RAFT agents that can be switched to offer good control over polymerization of both MAMs and LAMs and a route to polyMAM-b-polyLAM has been reported.[530–532] N-(4-Pyridinyl)-N-methyldithiocarbamates (275–279) are effective with LAMs and the corresponding N-(4-pyridinium)-N-methyldithiocarbamates (275-H+–279-H+) provide excellent control over the polymerization of MAMs (Table 13). In applying the RAFT agents in preparing polyMAM-b-polyLAM, the block comprising MAMs needs to be synthesized first. This sequence is necessary because, polyLAM• are poor homolytic leaving groups with respect to polyMAM• and, consequently, polyLAM-derived macro-RAFT agents have very low transfer coefficients in MAM polymerization. Attempts to synthesize poly(St)-b-poly(VAc) or other poly(St)-b-poly(LAM) starting from a poly(St) macro-RAFT agent gave no significant yield of polymer for an extended period (>4 h) corresponding to the time needed to convert the initial macro-RAFT agent.[530,531] This can be attributed to the very low rate of poly(St)• addition to VAc, possibly compounded by the presence of trace amounts of St monomer in the poly(St) macro-RAFT agent. A solution to this difficulty lay with forming an intermediate ‘block’ of poly(MA).[530,531]

There has been recent emphasis on RAFT polymerization in aqueous media for a variety of reasons which include: (i) perceived environmental benefits, (ii) control over polymerization of monomers with cationic, anionic, zwitterionic, and neutral polar groups which have limited solubility in organic media, and (iii) the need to perform polymerization under physiological conditions. Switchable RAFT agents have been proven effective in the aqueous solution polymerization of N,N-dimethylacrylamide (DMAm).[532] A quantitative study of the influence of acid type and concentration was performed for the polymerization of DMAm.[532] The conclusion was that best control over MAMs is achieved with stoichiometric amounts of a strong acid (e.g. toluenesulfonic acid). The polymerizations were performed with the tetraethyleneglycol macro-RAFT agent 279 which provided enhanced water solubility for the initial RAFT agent in its neutral (unswitched) form.

Polymerizations of LAMs (specifically NVP) in water with the switchable RAFT agents were complicated by the inherent instability of the NVP-based macro-RAFT agents in aqueous media aggravated by the presence of even trace amounts of acid.[532] The recent work of Destarac and co-workers suggests that this problem might be overcome with room temperature polymerization.[506,507] Block copolymers with LAMs were successfully prepared from the DMAm macro-RAFT agent in organic solution.

The N-aryl-N-(4-pyridinyl) dithiocarbamates (273, 274) are more effective (dispersities are lower) than the analogous N-(4-pyridinyl)-N-methyldithiocarbamates (278) with LAMs (NVC, VAc) in the unswitched (neutral) form and more active with MAMs (MA) in their switched (protonated) form.[115] Activity, as indicated by a higher Ctrapp or a lower Đ for the polymer formed, increases with the electron-withdrawing qualities of Ar–X. Some retardation was also observed with the more active RAFT agents of this class.

Other RAFT Agents

Other RAFT agents, namely those with Z = sulfonyl, phosphonate, or phosphine, are shown in Table 14.

The RAFT agents where Z is a strongly electron withdrawing alkyl or phenylsulfonyl group (280, 281) are prone to undergo direct reaction with (meth)acrylate monomers (BA, MA, tBA, and MMA) under polymerization conditions with consumption of the thiocarbonylthio group and ultimately little control over the polymerization.[546] A hetero-Diels Alder mechanism was suggested. Good control was achieved only for iBoA with 280 where the side reactions with monomer were suppressed by steric factors due to the bulky ester substituent.[546,547]

RAFT Agent Selection

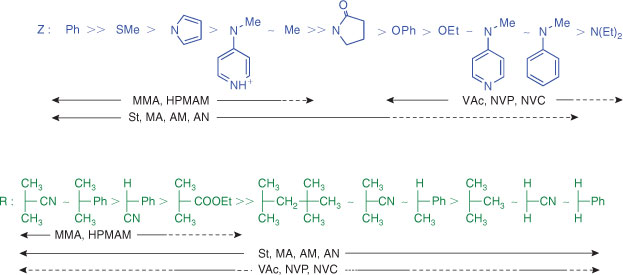

Monomers can be considered as belonging to one of two broad classes. The ‘more-activated’ monomers (MAMs) are those where the double bond is conjugated to an aromatic ring (e.g. St, 4VP) a carbonyl group (e.g. MMA, MA, Am) or a nitrile (e.g. AN). The ‘less activated’ monomers (LAMs) are those where the double bond is adjacent to saturated carbon (e.g. DADMAC), an oxygen or nitrogen lone pair (e.g. VAc, NVP) or the heteroatom of a heteroaromatic ring (NVC).

RAFT agents such as dithioesters (Z = aryl or alkyl) or trithiocarbonates (Z = alkylthio) suitable for controlling polymerization of MAMs, inhibit or retard polymerizations of (LAMs). Similarly RAFT agents suitable for controlling polymerizations of LAMs such as N,N-dialkyl- or N-alkyl-N-aryl dithiocarbamates and xanthates tend to have low transfer constants and are ineffective with MAMs.

Fig. 4, which is based on that in our previous reviews but is updated to include switchable RAFT agents,[17–19,137,550] provides a general summary of how to select the appropriate RAFT agent for particular monomers. Note should be made of the dashed lines in the chart. Although some control might be achieved with these monomer–RAFT agent combinations, the molar mass distribution may be broad or there may be substantial retardation or a prolonged inhibition period. This proviso has been omitted in some representations of this data in the literature. The data is presented in another form in Table 15.[551] There are several examples that have been reported (see Tables above) which fall outside of these guidelines and where good control (i.e. low dispersities, successful block synthesis) has, nonetheless, been achieved.

|

|

Synthesis of RAFT Agents

The methods most commonly exploited for the synthesis of (low molar mass) RAFT agents are listed below. The method of choice is dependent on the structure of the desired RAFT agent, the amount required, the toxicity and ease of handling of reagents, and other factors. We have recently completed a critical review of synthetic methods for RAFT agent synthesis which provides further details of the methods listed below.[28]

-

Reaction of a carbodithioate salt with an alkylating agent. O’Reilly and Hansell[474] have published on the synthesis of multifunctional trithiocarbonates The general conditions involve the use of acetone as solvent and phosphate as base as reported in a previous study from the same group.[552]

-

Reaction of a dithiochloroformate or a thiocarbonyl-bis-imidazole with nucleophiles. The esterification of a thiophenol with benzyl dithiochloroformate (e.g. Scheme 4) was used in the synthesis of a series of phenyl trithiocarbonates.[108] The dithiochloroformate may be replaced with the corresponding imidazolide to avoid use of thiophosgene (Scheme 5).[108]

-

Addition of a dithioacid across an olefinic double bond.

-

Radical-induced decomposition of a bis(thioacyl) disulfide.

-

Sulfuration of a thioloester or other substrate.

-

Radical-induced ester exchange.

-

Transesterification (thiol exchange by reaction of a dithioester with a thiol).

-

Base-catalyzed reaction of an activated halide (benzylic halide) with elemental sulfur.

-

Ketoform reaction (used for the synthesis of carboxy functional RAFT agents).

|

|

Many RAFT agents are derived indirectly by modification of other RAFT agents. Further description of those procedures used for the synthesis of macro-RAFT agents from polymers (and biopolymers) formed by non-RAFT processes appears in the section on block copolymers below.

-

Single monomer unit insertion. Chen et al.[433] have published further examples of the synthesis of RAFT agents (150, 151) or macro-RAFT agents (152, see section on block copolymers below) by insertion of a single monomer unit into an existing RAFT agent. Houshyar et al.[109] examined the scope of RAFT single-unit monomer insertion for sequential insertion of St and NIPAm in detail. Critical factors for success were found to be a high transfer constant for the RAFT agent, such that only one monomer unit was added per activation cycle, and a high rate of addition of the radical (R•) to monomer relative to that for further propagation. Single unit monomer insertion can also be favoured over polymerization by use of equimolar amounts of monomer and RAFT agent. Zard and co-workers have reviewed[37] and reported further applications[492,553] of the use of single unit insertion of non-activated monomers into xanthates in organic synthesis. For example, insertion of N-vinylphthalimide provides a synthetic route to amines.[492]

-

Esterification or amidation (carbodiimide)

-

Esterification (acid chloride)

-

Esterification (Mitsunobu reaction)

-

Esterification (other)

-

Active ester-amine reaction or active ester-thiol reaction

-

1,3-Dipolar cycloaddition

-

Other methods

Examples of these processes are found in Tables 5–14 above.

Characterization of RAFT Agents and RAFT-Synthesized Polymers

Most papers on RAFT polymerization contain information on the characterization of RAFT agents, RAFT-synthesized polymers, and/or the RAFT process. In this section we consider papers where the characterization of RAFT agents and RAFT-synthesized polymers by spectroscopic or chromatographic methods is a primary focus.

The UV-visible spectra of an extensive series of an RAFT agents (ZC(= S)SR) have been examined.[554] The position of the absorbance maxima for the π–π* and n–π* transitions and the molar absorptivities were found to be dependent on both the ‘Z’ and ‘R’ substituents. Thus, changes in UV-visible spectra on conversion of an initial RAFT agent to a macro-RAFT agent need to be considered when using spectrophotometry to follow the course of RAFT polymerization. The crystal structure of the RAFT agent 2-[(dodecylsulfanyl)carbonothioylsulfanyl]propanoic acid (155) has been published.[555]

Two reviews contain significant reference to RAFT synthesized polymers.[556,557] The first details recent applications of mass spectrometry, in particular the matrix-assisted laser desorption/ionization (MALDI) and electrospray ionization (ESI) techniques, in polymer chemistry. The other is on application of multidimensional chromatography to polymers.[557] This typically involves some combination of high-performance liquid chromatography (HPLC) to separate a polymer sample according to composition and size-exclusion chromatography (SEC) or gel permeation chromatography (GPC) to separate according to molecular weight.[558]

Two dimensional HPLC/GPC methods have been applied to characterize poly(EHA)-b-poly(MA) formed by RAFT dispersion polymerization,[275] the block copolymers formed by hetero-Diels Alder coupling of RAFT-synthesized poly(iBoA) with ATRP-synthesized poly(MMA),[294] and the block and star-poly(St)-PCL formed by sequential RAFT and ring-opening polymerization.[319]

A combination of LC/MS and LC/FTIR was used to characterize poly(NVP) formed with an acid functional xanthate RAFT agent.[498] The rather poor control observed was attributed[498] to extensive chain transfer to dioxan (solvent). The likely acid-catalyzed degradation of the xanthate chain end was not mentioned.

Toxicity of RAFT-Synthesized Polymers

Many recent papers have explored the potential toxicity of RAFT-synthesized polymers. These polymers appear to be generally well tolerated in biological systems.

-

Pissuwan et al.[559] found that, while poly(HPMAm)-dithiobenzoate showed some toxicity with three cell-lines when used at very high concentrations (1000 μM) but were well tolerated when used at lower concentrations (<200 μM), similar polymers with trithiocarbonate ends were non-toxic under all conditions.

-

poly(DMAEMA)-b-poly(HEMA)-dithiobenzoate were shown to have low cytotoxicity with relation to block copolymers based on polyethyleneimine.[217]

-

poly(DMAEA)-trithiocarbonate was shown to have low cytotoxicity and to degrade under physiological conditions to poly(AA).[444]

Polymerization Kinetics

Kinetic simulation is frequently used as a tool to correlate experimental data with theoretical models. The use of RAFT polymerization and kinetic simulation with Predici have been applied to determine chain length dependent termination rate constants in radical polymerizations using the RAFT-CLD-T method.[29] Kinetic simulation has also been used to study the mechanism of microwave-assisted RAFT polymerization of styrene (see below).[560] Kinetic simulation with a method of moments was used to model the effect of backmixing on the outcome of RAFT polymerization for a plug flow tubular reactor or for multiple continuous stirred tank reactors connected in series.[561]

On-line monitoring of RAFT polymerization has been performed using ACOMP (automatic continuous online monitoring of polymerization reactions).[221,439,562] This technique involved passing a stream from the reaction mixture through a series of detectors including a multi-angle light scattering detector, a differential refractometer, a single capillary viscometer, and a photodiode array UV/visible spectrophotometer to provide on-line data on the variation of molecular weight and copolymer composition with polymerization time. The method has been applied to study the homopolymerization of BA in butyl acetate,[439] the copolymerization of BA with MMA,[562] and the copolymerization of DMAEMA with styrene in DMF[221] all with RAFT agent 155.

Reaction Conditions (Initiator, Temperature, Pressure, Solvent, Lewis Acids)

The general guideline for choosing initiator concentrations for RAFT polymerization is that the mole ratio of RAFT agent to amount of initiator decomposed should be >10 : 1 and be such that the molar mass obtained in a control experiment (i.e. same conditions without RAFT agent) is at least 10-fold higher than the desired molar mass.[17] It must be remembered that for every pair of radicals generated, a pair of radicals will terminate to provide dead polymer impurity.

In some cases, it may be necessary to use a higher than desirable initiator concentration to achieve a more acceptable rate of polymerization. Before taking this step, avoidable causes of retardation need to be considered. These causes include: inappropriate choice of RAFT agent, impurities in the RAFT agent (or other components of the polymerization medium), and ineffective exclusion of air or oxygen.

RAFT polymerizations have been successfully conducted at temperatures ranging from sub-ambient to 140°C (or higher under very high pressure). At lower temperature, transfer constants may be lower and retardation may become more important. At higher temperatures, the RAFT agent may be unstable. The importance of these phenomena depends on the specific RAFT agent and monomer combination.

ATRP-Initiated RAFT Polymerization

Several studies have appeared on the use of initiators normally associated with ATRP (halide or sulfonyl halide plus transition metal catalyst) to initiate RAFT polymerization. The process may use a variety of traditional ATRP or SET-RDRP and have been called SET-RAFT.[346,384] Examples include:

-

the use of a metalloenzyme (laccase) as an catalyst and ethyl bromoisobutyrate as initiator to perform RAFT polymerization of PEGMA in the presence of cyanoisopropyl dithiobenzoate (12).[185]

-

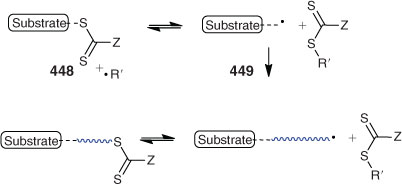

polymerization of MA with cyclic RAFT agent 444 and either ethyl 2-bromopropionate or 2-diethyl, meso-2,5-dibromoadipate as initiator and CuBr/tris[(2-pyridyl)methyl]amine catalyst.[563]

RAFT Agent Stability During RAFT Polymerization

Li et al.[221] have reported that some trithiocarbonate RAFT agents (18, 89, 155) are unstable during polymerization of DMAEA at 80°C in DMF. The RAFT agents were stable during BA and St polymerization under similar conditions and a lower rate of degradation was observed in the case of DMAEA/St copolymerizations. The result is surprising since many other groups have reported no specific difficulties in RAFT polymerization of this or other monomers with tertiary amine functionality.

Oxidation of the RAFT agent/end-group was proposed to account for loss of living character during RAFT polymerization of St with 1-phenylethyl dithiobenzoate in air.[162]

RAFT polymerization is not usually compatible with unprotected primary or secondary amines. Janoschka et al.[209] have reported that RAFT polymerization can be successfully carried out in the presence of an unprotected hindered amine (2,2,6,6-tertramethylpiperidene) functionality in the methacrylate 194. However, the polymerization had to be conducted in aqueous ethanol as solvent (polymerization was not successful in toluene) and with a higher than usual concentration of initiator.

Microwave-Assisted RAFT Polymerization

Three reviews on microwave-assisted polymerization[65,98,99] and two reviews specifically on microwave-assisted RAFT polymerization[30,31] have appeared. The number of papers on RAFT polymerizations accelerated by microwave heating continues to increase. Recent examples include RAFT polymerization of MMA,[564] acrylamides (NIPAm, DMAm) and their block copolymers,[392] vinylsilazane (452),[535] and vinyl esters (VAc, VBz, VPv) and their block copolymers.[523] Each of these studies indicate substantial acceleration of polymerization with respect to similar conventionally heated polymerizations.

Controversy over the extent and mechanism of acceleration of the rate of RAFT polymerization continues. Two groups[560,565] have reported on kinetic-modelling of microwave accelerated RAFT polymerization of St in an attempt to gain further understanding of the process. Both came to the conclusion that there is a ‘microwave effect’. The first study[560] attributed accelerated polymerization to an additional initiation process. The second study[565] discounted this possibility and proposed that the results were consistent with the rate constants for addition to monomer (kp) and RAFT agent (kadd) both being accelerated to the same extent by microwave irradiation.

In two independent studies[366,391] of accelerated RAFT polymerization in conventionally heated continuous-flow tubular reactors (see below), microwave-heated batch RAFT polymerizations were conducted as control experiments. No significant differences in polymerization kinetics were observed. These results suggest there is no ‘microwave effect’ beyond that of rapid heating of the reaction medium.

In their perspective, Kempe et al.[99] conclude with reference to apparent ‘microwave effects’ that ‘most of the differences seem to be ascribable to the application of different equipment’ and that ‘these differences might be due to a non-exact control and measurement of the temperature and inhomogeneous electric fields’. In the absence of other data, we concur with this conclusion.

RAFT in Continuous Flow

Solution RAFT polymerization of MMA, BA, VAc, NIPAm, and DMAm has been performed in tubular reactors.[366,391] It was important to degass the polymerization medium and to use metal (stainless steel) tubing for the process.[366] Under these conditions low dispersity polymer similar to those obtained in batch (microwave heated) experiments were obtained. Oxygen-induced inhibition was observed with the use of standard PFA tubing.[366] A procedure for sequential RAFT polymerization and end-group removal in a single flow process has also been reported.[566]

Models have been developed to describe RAFT polymerization in tubular reactors or a series of continuous stirred tank reactors (CSTRs) or a combination of these. Kinetic simulation was then used to predict residence time distributions and the effect of backmixing on the outcome of the process.[561,567] The effect of backmixing is to produce a higher dispersity and a lower average chain length than that expected based on reagent concentrations and conversion, thus it becomes important to exclude reactor backmixing as much as is possible.[561] Methods have also been developed to allow prediction of the monomer sequence distribution for such reactors.[567]

A droplet microfluidic reactor has been described and used to prepared low dispersity poly(St)-b-poly(MMA).[534]

RAFT Polymerization in Ionic Liquids

Ionic liquids have been reported to significantly enhance both the reaction rate and polymer molecular weight in radical polymerization. These effects have been attributed to a reduction in the termination rate constant. Barth et al.[29] have used SP-PLP-EPR measurements to determine termination rate constants (kt) for MMA-d8 polymerization in 1-butyl-3-methylimidazolium tetrafluoroborate ([bmim]BF4) and 1-ethyl-3-methylimidazolium bis(tri-fluoromethylsulfonyl)imide ([emim]NTf2). Both the average <kt> and the value of kt1,1 for reaction between single unit chains were significantly reduced with respect to values for bulk MMA.

Control of Stereochemistry in RAFT Polymerization

Smith et al.[521] observed a higher than usual tacticity (probability of a racemo dyad r = 100 × [rr + mr/2]/[rr + mr + rr] = 69 ± 8 %) for a low molar mass (Mn 1000) poly(VAc) prepared by RAFT polymerization with xanthate 235 at 50°C. A value of r of 53 % was obtained for higher molar mass (Mn > 1300) poly(VAc) for temperatures in the range 37–60°C.

The tacticity of low molar mass NIPAm (Mn 4000) prepared with trithiocarbonate (79) was found to be significantly more syndiotactic (r = 58.6 %) than NIPAm produced by conventional radical polymerizations (without RAFT agent r = 54.6 %).[321] This was attributed to an effect of the acid functional end-group. The syndiotacticity was further enhanced (r = 61.1 %) for polymerization with 3-methyl-3-pentanol as cosolvent.

In order explore the effects of molecular weight and tacticity on the glass transition temperature, Biswas et al.[316] prepared poly(NIPAm) (Mn in the range 70000–100000) with differing tacticity by RAFT polymerization with dithioester 73 in the presence of yttrium triflate (Y(OTf)3) at 60°C. r was in the range 53 % (no Y(OTf)3) to 12 % (0.266 M Y(OTf)3). Katsumoto et al.[284] prepared poly(DEAm)s with differing tacticity by RAFT polymerization in the presence of Y(OTf)3 or Sc(OTf)3.

A high syndiotacticity was obtained in RAFT polymerization of the donor–acceptor–donor monomer, N-(6-acetamidopyridin-2-yl)acrylamide (359), with either 11 or 93 in the presence of 1-octylthymine at 60°C.[170] The value of r was raised from 44 %, for no 1-octylthymine, to 73 %, with 2 molar equivalents of 1-octylthymine with respect to monomer.

A process for forming stereogradient poly(MMA) has been described.[173] The process involves RAFT copolymerization of MAA with a bulky methacrylate such as TPMMA or 1-phenyldibenzosuberyl methacrylate (293) with 11 in toluene solution. Under these conditions, MAA showed increased reactivity, attributed to hydrogen bonding, and was consumed slightly faster than either TPMMA or 293. The copolymers were converted into homo-poly(MAA) by the acid hydrolysis and then to homo-poly(MMA) by esterification with trimethylsilyldiazomethane. The fraction of isotactic triads in the poly(MAA) changed gradually from mm = 14 % to nearly 100 %. RAFT copolymerization of TPMMA and MAA in 1,4-dioxane resulted in consumption of MAA and the bulky methacrylate at the same rate and an atactic polymer (rr/mr/mm = 38/49/13).

RAFT Polymerization in Heterogeneous Media

Several reviews that relate to the use of RAFT in heterogeneous media have appeared[32,96,97] including a tutorial review on RAFT in microemulsion.[32] Examples of RAFT polymerizations in heterogeneous media are included in Tables 3–14 and are distinguished in the tables by the monomer appearing in italics.

Ab initio RAFT emulsion polymerization has been plagued by problems of retardation, colloidal instability, poorly defined molecular weight distributions and broad, possibly multimodal, particle size distributions. Success was strongly dependent on the specific RAFT agent and the monomers polymerized. This is attributed in part to the slow transportation of the RAFT agent between the droplet phase and the particle phase and in part to the way in which molecular weight distributions evolve during RAFT polymerization. Those RAFT experiments in heterogeneous polymerization that were successful were mostly multistep processes, used amphiphilic macro-RAFT agents, and/or made use of miniemulsion or seeded emulsion techniques.

The use of amphiphilic macro-RAFT agents as stabilizers in ‘surfactantless’ polymerization by emulsion, miniemulsion, dispersion and other methods continues to attract attention. Recent examples include:

-

One pot RAFT dispersion polymerization to form PEO-b-poly(St) vesicles in methanol using PEO-macro-RAFT agent 132,[410] and form poly(GMA)-b-poly(HPMA) in water using a poly(GMA) macro-RAFT agent (GMA units are present as 2,3-dihydroxypropyl methacrylate units).[186]

-

Sequential formation of PEGA/MMA macro-RAFT agent (by solution polymerization) and low dispersity poly(PEGA-co-MMA)-b-poly(St) (by emulsion polymerization) in a one-pot process.[354,360] The same macro-RAFT agent was also used in non-aqueous emulsion or dispersion polymerization of BzMA.[361]

-

Hollow nanoparticles were prepared by miniemulsion polymerization of MMA with DVB crosslinker using a MAA/MMA macro-RAFT agent.[368]

-

Shell-crosslinked fluorinated nanocapsules were prepared by miniemulsion polymerization of HA/DFHA with DVB crosslinker using a MAA/DFHA macro-RAFT agent.[369]

-

Emulsion polymerization of VAc was performed with a xanthate-terminated dextran as RAFT agent.[568]

-

Gradient copolymers of TFEMA and AA were synthesized using an amphiphilic RAFT agent and starved feed addition of TFEMA.[438]

-

Emulsion or dispersion polymerization was carried out in supercritical CO2 of VAc with a PEO macro-RAFT agent (245),[526] of MMA with a PDMS macro-RAFT (148),[431] or of NVP with VAc/VPv[513] macro-RAFT agents agent as stabilizer.

-

See also the section below on Microgels and Nanoparticles and Table 24 for examples of RAFT crosslinking polymerization.

RAFT miniemulsion polymerization of St was performed in supercritical CO2 at 50°C with trithiocarbonate 175, an aqueous phase initiator (VA-044), and the anionic surfactant Dowfax 8390.[458] It was found that the particle size could be tuned by changing the CO2 pressure while keeping the recipe constant, with 6.00, 6.50, and 7.50 MPa, generating number-average particle diameters of 98, 89, and 48 nm, respectively.

It has also been found that, particularly in ab initio processes, improved control and colloidal stability is obtained for monomer RAFT agent combinations which have a lower transfer constant. In this context several groups have studied the kinetics of the RAFT emulsion polymerization of St[495,510] with xanthate RAFT agents. A detailed study of RAFT microemulsion of BA with xanthate RAFT agents has also been performed.[32,500,501] It was found that a simplified RAFT mechanism (kadd = ktr, no intermediate radical termination) allowed the kinetics of the microemulsion polymerization of BA with a xanthate RAFT agent to be quantitatively predicted.[32,500] With this model, the value of kβ was found to be important in determining the monomer conversion. Another study used kinetic simulations of a RAFT microemulsion polymerization to show that retardation and inhibition can be explained through consideration of the exit and re-entry of the R• radicals without invoking ‘slow fragmentation’ or ‘intermediate radical termination’ phenomena.[569] Note, however, that the finding that data can bit fit by a simple model does not prove that model.

RAFT polymerization of DMAm in inverse microemulsion has been described.[326,570] The process has been performed with a series of trithiocarbonate RAFT agents.[326] The relative efficacy of these was attributed to the partition coefficient between the aqueous and oil phase.

Polymer self-assembly may be considered an integral part of the initial phase of heterogeneous polymerization and it is well known that amphiphilic polymers of various architectures undergo spontaneous self-assembly in aqueous solution to provide a wide range of nanostructures, which include spherical, worm-like and rod-like micelles, vesicles, nanotubes, and toroids. Nonetheless, the (RAFT) polymerization induced self-assembly and the factors which control what structure is formed have recently attracted considerable interest with studies on the phenomenon in emulsion polymerization,[354,381,400] dispersion polymerization[187,224,229,353,361,571] and non-aqueous dispersion polymerization.[394,397] Blanazs et al.[187] have constructed a phase diagram for poly(288)–poly(HPMA). Refer also to Table 24 for examples of the synthesis of microgels and core-crosslinked star polymers by RAFT-mediated radical crosslinking polymerization most of which can be considered as dispersion polymerizations.

|

|

|

|

|

|

|

|

|

RAFT Polymer Syntheses

Polymer syntheses by RAFT polymerization are summarized in Tables 3–14. Only systems which require separate comment are mentioned here or in the subsequent sections. Some of the more exotic monomers subjected to RAFT polymerization are included in the tables that follow. They include methacrylates (Fig. 5), acrylates (Fig. 6), methacrylamides (Fig. 7), acrylamides (Fig. 8), styrene derivatives (Fig. 9), and vinyl monomers (Fig. 10). Monomers of the above classes with reactive functionality appear in Figs 11 and 12. There continues to be substantial interest in RAFT polymerization of various biorelated monomers which include those derived from amino acids,[572] such as acrylamides 363–368 (Fig. 8), St derivative (384), and glycomonomers, such as methacrylates 312, 313, and 318–320 (Fig. 5), acrylates 341 and 351, methacrylamides 352–355, acrylamide 372, and St derivative 393. Note that such polymers are frequently also made by modification of polymers with reactive post-RAFT polymerization (e.g. those formed from monomers with active ester groups, Fig. 12).

|

|

|

|

|

|

Methacrylates

A wide range of methacrylates have been successfully polymerized, which include AAEMA, AEMA, AMA, CMA, BMA, BDSMA, DEGMA, DMAEMA, EGMA, HEMA, HMA, iBMA, LMA, MMA, MPC, PEGMA, PFPMA, TMAEMA, TMAPMA, TPMMA (see Abbreviations), (289–333) given in Fig. 5, and compounds 400, 407, 413, and 430. Low dispersities in RAFT polymerization of methacrylates require the use of a RAFT agent with a high transfer constant. This requires that the ‘Z’ group is suitable for MAMs and that the ‘R’ group is a good leaving group with respect to the methacrylate propagating radical. Suitable RAFT agents include dithiobenzoates, 11, 12, 18, and 40, trithiocarbonates, 95 and 98, and aromatic or switchable dithiocarbamates in their more active form, 275-H+ and 276-H+, and derivatives of these.

The polymers poly(NVC)-b-poly(311) and poly(NVC)-b-poly(314) were apparently prepared making use of a poly(NVC) macro-RAFT agent with xanthate RAFT agent 221 and, for the case of poly(NVC)-b-poly(314), good control (a low dispersity polymer) was reported.[496] However, O-alkyl xanthate RAFT agents do not normally provide good control over the polymerization of methacrylates.[573] Furthermore, the poly(NVC) propagating radical is anticipated to be a poor leaving group with respect to the propagating species formed from either 311 or 314.

Monomer 329 containing a xanthate functionality is included in Fig. 6 because with ‘R’ = primary alkyl that functionality does not function as a RAFT agent. It was used as a precursor to a polythiol.

Acrylates

Acrylates mentioned in this survey include AEP, BA, CPA, DA, DEHEA, DMAEA, EA, EAA, EEA, EHA, iBoA, MA, PA, PEGA, tBA, and (334–351) listed in Fig. 6.

Acrylate esters undergo chain transfer to polymer during polymerization leading to branched and even gelled polymers. It has been reported that the extent of branching is higher for conventional radical polymerization than for RDRP (ATRP, RAFT, and NMP).[443] A qualitative explanation was proposed in terms of the differences in the concentrations of short-chain radicals between RDRP and conventional radical polymerization. Reys and Asua[574] have proposed an alternative explanation in terms of radical life times (the time between chain activation and deactivation) being of the same order of magnitude or shorter than the time required for the conformation change necessary for intramolecular hydrogen atom transfer. A recent paper suggests that conventional chain transfer agents (n-octanethiol)[575] and H-bonding solvents (n-butanol)[576] also reduce the extent of branching in conventional radical polymerization.

Methacrylamides

Many examples are appearing of RAFT (co)polymerization of HPMAm; particularly with respect to various bioapplications.[54] Other examples of methacrylamides monomers recently used in RAFT polymerization are the primary amino-functional monomers, AEMAm and APMAm, DEAPMAm, DMAPMAm, 409 and (352–358) shown in Fig. 7. The choice of RAFT agent for polymerization of methacrylamides is subject to similar constraints as mentioned for the methacrylates. In particular the ‘R’ group should be selected so as to be a good leaving group with respect to the propagating radical. The RAFT agents generally preferred include dithiobenzoate 18 and ethyl trithiocarbonate 97 and derivatives of these.

Acrylamides

Attaining low dispersities with RAFT polymerization of acrylamides requires a RAFT agent suitable for MAMs. Acrylamides include Am, AMPS, BzAm, CHAm, DAAm, DEAm, DMAm, DMAEAm, NIPAm, NAM, OAm (see Abbreviations) and (359–372) shown in Fig. 8.

Styrenics

Styrenic monomers subjected to RAFT polymerization include (373–393) in Fig. 9 plus 399, 404, 405, and 406. Good control over RAFT polymerization of St and derivatives requires a RAFT agent suitable for MAMs. Many of the functional styrenes in Fig. 9 have been used to prepare polymers for optoelectronic applications. The advantage of the styrenic monomers in this context is that the functionality is typically not attached through a potentially labile ester or amide linkage.

Diene Monomers

RAFT polymerization of diene monomers generally requires a more active RAFT agent and generally requires use of higher reaction temperatures to obtain good control and reasonable rate of polymerization (e.g. 125°C). RAFT homopolymerizations of BD and Ip in solution are slow.[437] The RAFT copolymerization of Ip with hydroxy-functional monomers, HEMA, HEA, and 394 (Chart 3), with trithiocarbonate (123) has been explored.[396] Diels Alder reaction of Ip with the (meth)acrylates was observed as a side reaction. The (meth)acrylates are consumed preferentially to Ip. thus their copolymers with Ip have a gradient structure. The copolymer of Ip with 394 had a more random structure.

|

Vinyl Monomers

Vinyl monomers in the present context include the vinyl esters (VAc, VB, VBz), the N-vinyl amides and imides (NVCL, NVPip, NVP, NVPI), the N-vinyl heteroaromatics (Vim, NVC), vinylsulfonates (BES, NES), vinylphosphonic acid (VPA), the haloolefins (VF2), and others in Fig. 10. Most of these monomers are LAMs (except 395) and good control over homopolymerization requires use of a RAFT agent suited for that class of monomer (usually a xanthate or a dithiocarbamate). Note, however, that good control over copolymerization of LAMs with MAMs can be obtained with RAFT agents suited to MAMs (e.g. NVPI/NIPAm with 251[517]).

The polymerization of NVP in aqueous media was reported as problematic due to the sensitivity of the macro-RAFT agent with a terminal NVP unit to hydrolysis. It has recently been shown[506,507] that this problem can be overcome by conducting the polymerization at ambient temperature with redox initiation.

A study on the use of benzyl and t-butyl trithiocarbonate and dithiobenzoate RAFT agents for VAc polymerization has appeared.[274] Intermediate radical termination was found to be a significant cause of retardation with these systems.

Monomers with Reactive Functionality

There is a need for processes for polymer modification post-RAFT polymerization (so-called polymer analogous reactions) that proceed in quantitative yield under mild reaction conditions. Several reviews on combined use of RDRP and ‘click chemistry’ have appeared.[66–72] The ‘clickable’ functionality may be present on the Z or R groups of the RAFT agent (see elsewhere in this review) or in the monomers. These monomers can be incorporated in blocks as a precursor to a polymer brush or copolymerized to provide sites for the attachment of functionality or for crosslinking. Many papers concern the combination of RAFT and azide-alkyne 1,3-dipolar cycloaddition. Some alkyne-functional monomers are listed in Fig. 11. Azide functionality is often incorporated post RAFT polymerization.

‘Active ester’ monomers that have been subject to RAFT polymerization (401–405) are shown in Fig. 12. These active ester groups undergo facile reaction with, in particular, substrates with primary amine functionality. Monomers with protected thiol, hydrazide or amino functionality that have been subjected to RAFT (co)polymerization are shown in Fig. 13.

|

Several recent papers have explored polymerization of monomers containing isocyanate or isothiocyanate functionality (Fig. 14).[192,243,288] RAFT polymerization and the thiocarbonylthio group is compatible with isocyanate functionality. However, some care must be taken in selection of the RAFT agent and other components of the polymerization medium such that they do not also contain other functionality that is inherently reactive (such as carboxy).[243]

|

Monomers 416 and 417 with ATRP initiator functionality include CMS and the monomers shown in Fig. 15.[203,587]

|

Crosslinking Monomers

Crosslinking monomers are used both in the synthesis of microgels and polymer networks (see below). This class of monomer includes DEGDMA, TEGDMA, EGDMA, TEGDA, HDDA, MBAm, DVB, and compounds 418–425 (Fig. 16). Use of the monomers such as 420, with an acetal linkage, and 421–423, with disulfide linkages, results in the formation of degradable crosslinks which can be important in controlled release applications. The crosslinks can also be cleaved to allow polymer analysis. See also the section Polymer Networks below.

|

Cyclopolymerization

Further studies on RAFT cyclopolymerization of DADMAC have been reported. The most recent work used xanthate (229)[113,506] or trithiocarbonate (155).[440] RAFT polymerization with xanthate (229) was controlled although dispersities were broad.[113,506] This was attributed to the low transfer constant of poly(DADMAC) macro-RAFT agent in the DADMAC polymerization (Table 1). With trithiocarbonate (155), while the polymerization showed some living character, conversions were low and dispersities were poor (Đ > 1.5) and the latter increased with monomer conversion.[440] While a trithiocarbonate RAFT agent is likely to have a higher transfer constant in DADMAC polymerization, intermediate radical fragmentation is likely to be slower making retardation more likely.

A 1 : 2 mixture of DVE and MAH with dibenzyl trithiocarbonate was reported to undergo alternating RAFT cyclocopolymerization to provide the polymer 426 as shown in Scheme 6.[341,342] Other studies on RAFT cyclopolymerization are summarized in Fig. 17.

|

|

Ring-Opening Polymerization

RAFT ring-opening polymerization provides a simple method of forming polymers with readily cleavable linkages, i.e. esters, thioesters, and/or disulfides, in the carbon–carbon backbone of a polymer chain.[276] The monomers 433–437 (Fig. 18) were copolymerized with MMA, DMAm, and HEMA.

|

End-Functional Polymers and End-Group Transformations

Processes for thiocarbonylthio end-group removal or transformation post RAFT polymerization continue to attract significant interest. Two reviews focussing on end functional polymer and end-group removal/transformation have appeared within the last two years.[33,34] A wide variety of methods are now available for removing or transforming the thiocarbonylthio groups in RAFT-synthesized polymers (Scheme 7[34]). All have advantages and limitations depending on the intended application. The thiocarbonyl functionality present in RAFT-synthesized polymers, once seen as a limitation to the wide-spread adoption of RAFT polymerization can now be seen as an enabling functionality in addressing the needs of the biomedical, optoelectronic, nanotechnology, and other sectors.

|

Radical-Induced Reduction

Radical-induced reduction allows the thiocarbonylthio group of a RAFT-synthesized polymer to be replaced with a hydrogen atom. Recent examples are shown in Table 16. Selective removal of the dodecyl trithiocarbonate ends from poly(CMS) (with pendant benzylic chloride functionality) was successfully performed with tri-n-butylstannane as the H-donor.[436]

Addition–Fragmentation Coupling

A popular method for end-group removal/transformation involves heating the RAFT-synthesized polymer with a large excess of a radical initiator, most often, an azo-compound. That most commonly used is AIBN. However functional azo-compounds (e.g. 438–440, Chart 4) have also been successfully used. Some recent examples are included in Table 17. The strategy appears generally successful for methacrylic polymers (Table 17). The expected complications from primary radical disproportionation are not reported. However, incomplete end-group removal is often found for acrylic and styrenic polymers.[194] The potential limitations of the technology and their causes are discussed in our recent review.[34]

|

Peroxide initiators (LPO, BPO) have been shown to be generally more effective than azo-initiators (e.g. AIBN) in achieving end-group removal.[593] However, the complication of termination by self reaction of propagating species is more pronounced. Chen et al.[194] have shown that a combination of a peroxide initiator (LPO) and azo-initiator (AIBN) is more effective than either alone (Scheme 8). Since the polymers formed are likely to possess end-groups from the peroxide and the azo-initiator, this strategy is most likely not suitable for preparing polymers with defined end-group functionality. The method has also been used as a degrafting process in silica-supported polymer synthesis.[594]

|

Radical-Induced Oxidation

It has been reported that addition of a very small amount of a CCT agent ([(CH3OH)2Co(dmgBF2)2] : [RAFT agent]0 = 1 : 80000) during the latter stages (~70 % monomer conversion) of a RAFT polymerization of a methacrylate monomer (MMA, BMA) provides complete end-group removal and a high purity low dispersity macromonomer product.[602] Details of the mechanism were not presented, however, a possible mechanism combining elements of those for the RAFT and CCT processes is shown in Scheme 9. The process can be considered as a radical-induced oxidation.

|

Reaction with Nucleophiles (Aminolysis/Hydrolysis/Ionic Reduction)

Conversion of thiocarbonylthio end-groups into thiol groups through reaction with nucleophiles is one of the most common end-group transformations. A list comprising recent examples is provided in Table 18. In order to avoid the complication of disulfide formation the process is commonly done in the presence of a reagent to trap the thiol. A summary of the transformations that have been used is provided below (see section entitled Click Reactions).[34]

It has been reported that the use of hydrazine as nucleophile is advantageous both in giving a very rapid reaction and little disulfide formation even when the process was carried out in air.[375] However, Lee et al.[176] found disulfide formation to be significant during the hydrazinolysis of St/AcS copolymers.

Oxidation

Thiocarbonylthio chain-ends of RAFT-synthesized polymers can be efficiently converted into hydroxy chain ends in high yield by heating a THF solution of the polymer and AIBN in air (to produce a polymer with hydroperoxy ends) and then treating this solution with triphenylphosphine.[182,605] The process was demonstrated for polymers with dithiobenzoate or dithiophenylacetate end-groups and for polymers with trithiocarbonate mid-groups (synthesized with dibenzyl trithiocarbonate) (Table 19).

End-groups of poly(MMA) and poly(St) formed with dithiobenzoate 12 are reported to be completely removed by heating a THF solution of the polymer in air.[180] The process was accelerated by addition of acid. The end-group removal process was proposed to involve hydrolysis of the dithiobenzoate to a thiol end-group, however, the end-groups formed were not fully characterized and it seems more likely that the process is analogous to that seen with AIBN/air in THF.

It has also been proposed that hydrogen peroxide can be used to directly transform RAFT end-groups to hydroxy end-groups.[608] The process was applied to poly(NVP) with xanthate chain ends and poly(St) with dithiobenzoate end-groups and involved heating the polymers with hydrogen peroxide at 60°C. The proposed mechanism involved thermal generation of hydroxyl radicals and an addition-fragmentation-coupling process (see below). However, while hydrogen peroxide may undergo induced decomposition, thermal homolysis requires relatively high temperatures.

A facile process in which alkaline hydrogen peroxide is used to transform dithioesters (ZCS2R) to a mixture of a carboxylic acid (ZCO2H) and a disulfide (RSSR) in very high yield has been reported[609] but has not been applied to polymeric substrates.