Repurposing gas fields for energy storage – a proposal for compressed air energy storage in the depleted Rolleston gas field

Xingjin Wang A * , Zhujun Wang A and Yudong Yuan AA

Dr Xingjin Wang is an experienced geologist and a well-known entrepreneur in the oil and gas industry. Xingjin holds a PhD in Applied Geology from the University of New South Wales and has over 30 years of international experience in gas exploration and production applications, as well as CO₂ sequestration in China and Australia. He is the Founder and Executive Chairman of Denison Gas Ltd. Xingjin served as the General Manager of Arrow Energy from 2007 to 2010. As a Technical Advisor to Gazprom, he was involved in a CSG pilot project in Siberia, Russia, from 2011 to 2014. Xingjin is an Honorary Professor at the University of Queensland and serves as the Vice President of SPE NSW/ACT Sector. |

Zhujun Wang is the Managing Director and a Co-Founder of Denison Gas Ltd. With over 30 years’ experience, he continuously brings engineering innovations to the oil and gas industry in China, Africa and North America. He has driven groundbreaking achievements as an executive at Great Wall Drilling Company and contributes to the commercialisation of tight gas and shale gas in Ordos Basin and Sichuan Basin in China. Zhujun holds Master and Bachelor degrees in Mechanical Engineering from Dalian University of Technology. He is an active member of SPE and has a number of registered patents in drilling and petroleum production enhancement. |

Dr Yudong Yuan is an Engineer with Denison Gas, responsible for research and development of renewable projects including CAES. He has over 15 years’ academic and industrial experience in reservoir engineering and environmental engineering. He specialises in reservoir characterisation, reservoir simulation as well as surface water and groundwater simulation. Yudong holds a PhD degree in Petroleum Engineering from the UNSW. He was a senior environmental consultant in JBS&G and research associate in UNSW before joining Denison Gas. |

Abstract

Transitioning to renewable energy is a global target, but the intermittent nature of renewables requires energy storage for a successful transition. Australia currently has a significant shortfall in longer term energy storage that can be efficiently deployed. This paper introduces a probable solution to that challenge: repurposing a depleted gas field in Rolleston, Central Queensland, into a compressed air energy storage (CAES) facility. Depleted gas reservoirs with proven seal, porosity and permeability, offer potential to be repurposed for CAES. The application of CAES using geological media was explored in Germany in 1978 and the USA in 1991. However, large-scale commercial deployment has been occurring only recently in China, where underground salt caverns are utilised for storage. Conceptual studies indicate a gas reservoir at Rolleston gas field could be transformed into a CAES plant of 600 megawatts (MW) and 12-hour duration. By leveraging its geological attributes, the reservoir has potential to significantly enhance the sustainability and reliability of Queensland’s power supply. This paper provides an overview of the proposed CAES project including its scope, progress to date and next steps.

Keywords: CAES, depleted gas reservoir, long duration energy storage, net zero emissions, renewable energy, Rolleston gas field.

Introduction

Achieving net-zero emissions is a key objective for Australia. Queensland has abundant space and sunshine for renewable projects in its inland regions, but vast distances to the high-demand east coast population centres pose a challenge. Pumped hydro offers large-scale energy storage; however, the former Pioneer-Burdekin Pumped Hydro was cancelled due to its high cost and the significant environmental impacts.

Compressed air energy storage (CAES) offers a potentially more viable and lower impact alternative. As shown in Fig. 1, CAES uses the excess renewable energy to pressurise the air through compressors and injects it into underground caverns/porous media. During periods of high power demand, the compressed air is withdrawn through wells to drive the turbines and generate electricity. The compression heat is stored in the thermal tank and reused to heat up the air in the expansion process, which increases the round-trip efficiency up to 72%.

Reservoir screening

The majority of CAES plants today are constructed on salt caverns. However, salt formation in Australia is scarce and mostly located in remote areas such as the Amadeus Basin in Northern Territory. Depleted gas reservoirs, of which Australia has many, are strong candidates for CAES due to their enormous underground volume and proven stable seals formed over millions of years. The advantages of depleted gas reservoirs for CAES have attracted interests from both industry and researchers (King and Apps 2014; Wang and Bauer 2017; King and Moridis 2022; Medeiros et al. 2022). It is recognised that candidate reservoirs should have properties, including:

High permeability to conduct high-rate air flow to generate the designed power

High reservoir pressure to ensure high energy and flow rate

Sufficient void volume to sustain stable working pressure over a long duration

A tight and mechanically stable seal to constrain the compressed air.

After reviewing the geological and production data of Denison’s gas fields in Denison Trough, the Freitag gas reservoir in Rolleston gas field has been selected as a favourable candidate for a CAES plant of 600 MW and 12-hour duration, i.e. 600 MW/7.2 GWh.

Reservoir pressure and permeability

The Freitag gas reservoir in the study area is buried at the depth of ~870–1000 m below the surface (Fig. 2a, surface elevation is ~200 m above sea level) with a thickness of up to 18 m in the centre of the four-way dip trap (Fig. 2b, c) and porosity of ~20%.

Burial depth below sea level (a), reservoir thickness (b) and a typical well log (c) of Freitag gas reservoir in Rolleston gas field.

Well testing on the Freitag gas reservoir at Rolleston-1 shows the initial reservoir pressure is 10.6 MPa at a depth of 900 m, indicating an over-pressured reservoir. Drill stem test analysis of Rolleston-16 shows permeability of 430 mD; and the permeability derived from production analysis is over 1000 mD. Troup et al. (2018) reported a porosity of 23–28% and permeability close to 4000 mD. For power generation of 600 MW, approximately 1400 kg/s of air flow, equivalent to approximately 100 million standard cubic metres per day (sm3/day), is required at the inlet of the turbine. The Darcy-level permeability of the Freitag sandstone has the potential to make this achievable.

Void volume

The ideal volume of the geological host should be at least 10–30 times the daily flow volume to avoid abrupt changes in reservoir pressure (King and Moridis 2022). Material balance analysis indicates that the original gas in place of the studied Freitag gas reservoir is approximately 800 million sm3, which is 16 times the 12-hour flow demand (50 million sm3) of the proposed CAES. This would maintain a stable pressure and avoid stress abruption to rocks.

Seals

The Freitag gas reservoir is predominantly composed of clean quartz sandstone, sealed by 100–140 m marine shale on the roof, and 10–20 m mudstone on the floor (Fig. 1). The tight shale and mudstone fully wrap the sandstone reservoir on all sides. Prior to recent developments, the gas pool persisted for millions of years, underscoring the robustness of the seal conditions. This historical longevity attests to the field’s suitability for CAES.

Reservoir simulation

The commercial simulator tNavigator was employed to evaluate the air productivity of the Freitag gas reservoir for the proposed 600 MW/7.2 GWh CAES plant. The Freitag Formation is represented by 44 × 69 × 10 cells. Porosity and permeability are interpolated to the cells, with a range of 8–25% for the porosity and a range of 400–1500 mD for the permeability. The east-west extended fault (Fig. 2) is incorporated with zero transmissibility. In the central area where the permeable sand developed, 42 injection/withdrawal wells are distributed at distances of 100–200 m.

In the initial stage, it is assumed the residual gas was displaced by nitrogen (N2) to be below the combustion threshold and air was injected into the reservoir to the original reservoir pressure. The simulation lasts for 30 days, with alternative 12-hour withdrawal and 12-hour injection at a time step of 2 hours. During withdrawal, minimum bottomhole pressure (BHP) of 6 MPa is set for all wells and maximum flow rate ranging from 1.3 to 3.8 million sm3/day is assigned for the wells. During injection, original reservoir pressure is set as the maximum BHP and the same maximum rate is assigned to wells.

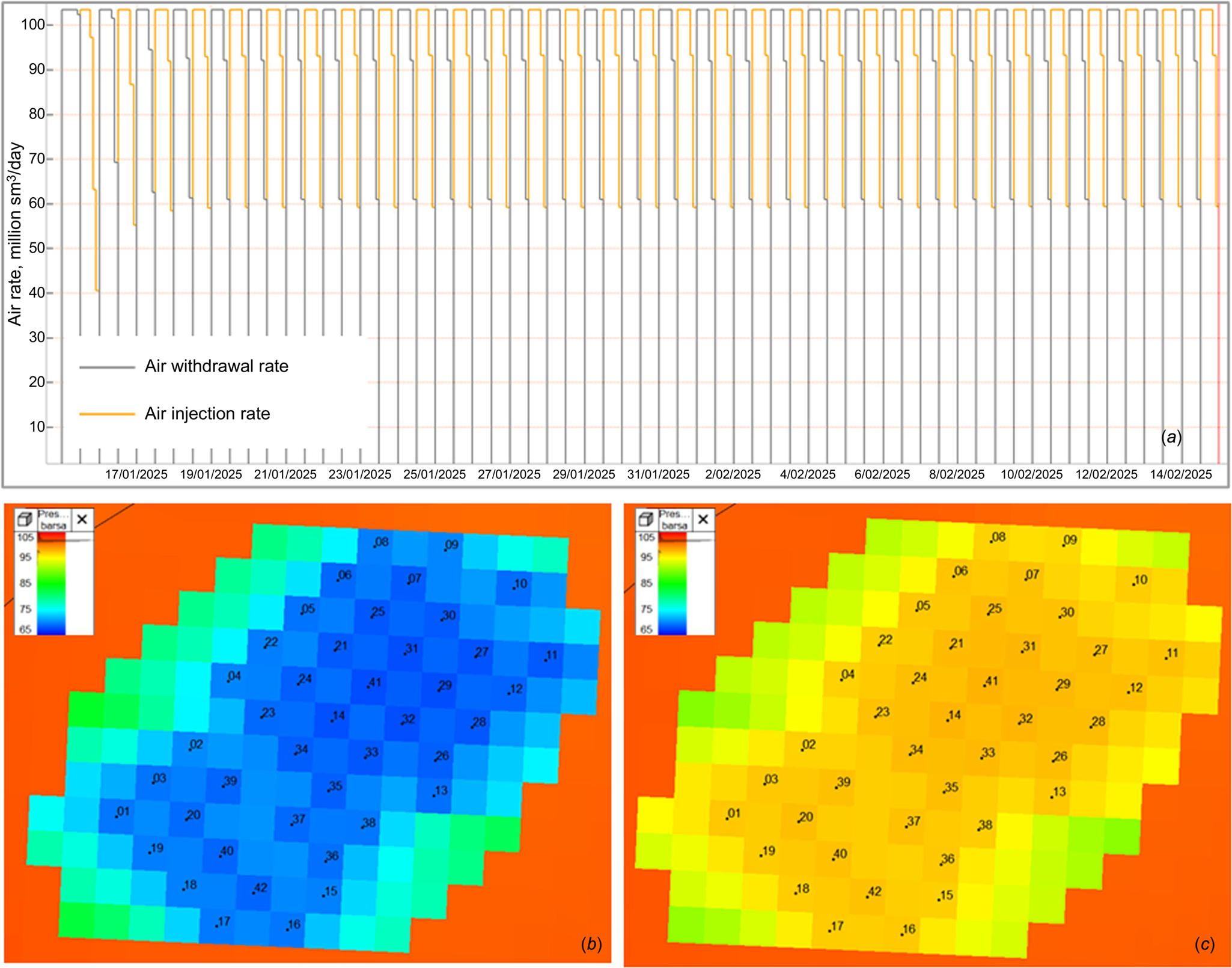

On Day 1, the air withdrawal rate is constant at 103.4 million sm3/day in the first 10 hours and slightly drops to 102.4 million sm3/day in the last 2 hours (Fig. 3a); at the end of withdrawal, the reservoir pressure in the well-dense area drops to approximately 6.5 MPa with higher values of 8–9 MPa at the edge of the trap (Fig. 3b). The following air injection rate is maintained at 103.4 million sm3/day in the first 6 hours but drops to 97.3, 63.3 and 40.6 million sm3/day in the next 3 time steps, respectively (Fig. 3a). Less air is injected than withdrawn and therefore the average reservoir pressure is below its initial status, especially at the edge of the trap (Fig. 3c).

Air withdrawal/injection rate in 30 days (a), reservoir pressure at the end of withdrawal (b) and at the end of injection on Day 1 (c).

Due to this pressure loss, the air withdrawal rate drops below 100 million sm3/day in the last 2 hours on Day 2 and in the last 4 hours from Day 3 onwards. A pattern is developed from Day 4 onwards. The withdrawal/injection rate maintains at 103.4 million sm3/day in the first 8 hours but drops to ~92 and ~60 million sm3/day in the last 2 time steps. Due to the inadequate air flow, the power generation would therefore be below 600 MW in the last 4 hours. To resolve this inadequacy, probably more wells are needed to drain and recharge the reservoir more effectively.

Generally, it indicates the Freitag gas reservoir has the potential to deliver the required air flow for the 600 MW/7.2 GWh target. According to the current simulation, the deliverability of the 42 wells declines due to the pressure loss as time goes on. This could be improved by more wells with optimised well distribution, or the proposed capacity of the CAES should be adjusted to be more consistent with the reservoir deliverability, with both requiring further analysis.

Concept definition

Repurposing a depleted gas reservoir for CAES incorporates multiple elements including a source of renewable power, gas reservoir, grid connection and environmental impact analysis.

As presented, the Freitag gas reservoir in the Rolleston gas field is selected for the proposed CAES project. Given the project is the first of its kind, a 10 MW/120 MWh pilot has been designed and a regulatory framework is needed, for example, to legislate the maximum injection pressure of the compressed air. Before air injection, N2 injection would be implemented to displace the residual methane to avoid combustion. A GW-scale solar farm might be constructed as the source of renewable power. Extension of the high-voltage transmission line to the proposed site is required to transmit the clean energy to east coast cities.

These key elements including regulation establishment, extension of transmission line and the pilot have been initiated and progressing with relevant parties.

Conclusion

Repurposing a depleted gas reservoir in the Rolleston gas field into a long-duration CAES could harness the abundant solar resource in central Queensland and help facilitate the Government’s energy transition targets. The Freitag sandstone, with its desirable reservoir properties, is favoured for the proposed 600 MW/7.2 GWh CAES plant. Potential air leakage is derisked by the seal of tight thick shale formed over millions of years. Reservoir simulation indicates that the deployed 42 wells could deliver adequate air for the surface facilities in the first 8 hours, but more wells are needed for a sustainable 12-hour operation.

A broad and close cooperation between the gas reservoir owners, landowners, regulatory departments and the transmission operator is crucial to make this project successful and duplicatable in other gas fields, and ultimately create a cleaner future.

Data availability

The data that support this study cannot be publicly shared due to ethical or privacy reasons and may be shared upon reasonable request to the corresponding author if appropriate.

Acknowledgements

The authors would like to acknowledge Lucy Snelling, Head of Commercial of Denison Gas, for her contribution to the wording of this paper.

References

King M, Apps DJ (2014) Compressed Air Energy Storage: Matching the Earth to the Turbomachinery – No Small Task. Available at https://www.sandia.gov/ess-ssl/EESAT/2013_papers/Compressed_Air_Energy_Storage_Matching_the_Earth_to_the_Turbo-Machinery_-_No_Small_Task.pdf

King MJ, Moridis G (2022) Compressed Air Energy Storage in Aquifer and Depleted Gas Storage Reservoirs. In ‘Advances in Energy Storage: Latest Developments from R&D to the Market’. (Ed. A Hauer) pp. 391–407. (John Wiley & Sons) 10.1002/9781119239390.ch19

Troup A, Longdon N, Gorton J (2018) Petroleum Plays of the Bowen and Surat basins. ASEG Extended Abstracts 2018, 1-10.

| Crossref | Google Scholar |

Wang B, Bauer S (2017) Compressed air energy storage in porous formations: a feasibility and deliverability study. Petroleum Geoscience 23, 306-314.

| Crossref | Google Scholar |

Dr Xingjin Wang is an experienced geologist and a well-known entrepreneur in the oil and gas industry. Xingjin holds a PhD in Applied Geology from the University of New South Wales and has over 30 years of international experience in gas exploration and production applications, as well as CO₂ sequestration in China and Australia. He is the Founder and Executive Chairman of Denison Gas Ltd. Xingjin served as the General Manager of Arrow Energy from 2007 to 2010. As a Technical Advisor to Gazprom, he was involved in a CSG pilot project in Siberia, Russia, from 2011 to 2014. Xingjin is an Honorary Professor at the University of Queensland and serves as the Vice President of SPE NSW/ACT Sector. |

Zhujun Wang is the Managing Director and a Co-Founder of Denison Gas Ltd. With over 30 years’ experience, he continuously brings engineering innovations to the oil and gas industry in China, Africa and North America. He has driven groundbreaking achievements as an executive at Great Wall Drilling Company and contributes to the commercialisation of tight gas and shale gas in Ordos Basin and Sichuan Basin in China. Zhujun holds Master and Bachelor degrees in Mechanical Engineering from Dalian University of Technology. He is an active member of SPE and has a number of registered patents in drilling and petroleum production enhancement. |

Dr Yudong Yuan is an Engineer with Denison Gas, responsible for research and development of renewable projects including CAES. He has over 15 years’ academic and industrial experience in reservoir engineering and environmental engineering. He specialises in reservoir characterisation, reservoir simulation as well as surface water and groundwater simulation. Yudong holds a PhD degree in Petroleum Engineering from the UNSW. He was a senior environmental consultant in JBS&G and research associate in UNSW before joining Denison Gas. |