Swathing subterranean clover (Trifolium subterraneum) does not suck: a promising alternative to vacuum seed harvesting

R. C. Wiese A B * , M. H. Ryan A B , P. G. H. Nichols

A B * , M. H. Ryan A B , P. G. H. Nichols  A C , W. M. Moss A B D , B. Wintle A , Y. A. Zago A , L. Hunt

A C , W. M. Moss A B D , B. Wintle A , Y. A. Zago A , L. Hunt  A , A. Hamblin A C and A. L. Guzzomi B C D

A , A. Hamblin A C and A. L. Guzzomi B C D

A

B

C

D

Abstract

Buried seeds of subterranean clover (Trifolium subterraneum) are typically harvested using the suction-based Horwood-Bagshaw Clover Harvester (HB) in late summer after preparatory tillage. This method relies on outdated equipment and causes significant soil disturbance. Swathing offers a promising alternative, whereby roots are cut and the sward windrowed before senescence for subsequent pickup and threshing once dried.

This study compared seed extraction efficiency and quality between swathing using a modified peanut digger as a first harvesting step and conventional HB harvesting.

Trials on a commercial subterranean clover seed crop in Capel, Western Australia, compared swathing using a modified peanut digger on 25 November and 1 December 2022 followed by hand collection of seeds to a single HB pass following standard tillage (14 February 2023). Measurements included canopy greenness, shoot biomass, soil moisture, seed extraction efficiency, seed weight, germination and seedling vigour.

Potential seed yield did not differ among treatments. As a first harvesting step, swathing achieved 100% (25 November) and 84.2% (1 December) seed extraction, compared to 61.3% for harvesting with the HB. November-swathed seeds had 82.6% germination, while December swathed (98.0%) and HB harvested (97.5%) had comparable germination. Seedling emergence followed the same trend. Swathed seeds weighed 17.1% (25 November) and 12.0% (1 December) less than HB-harvested seeds; however, seedling dry weights were mostly equivalent.

Although early swathing slightly reduced seed quality, swathing as a first harvesting step outperformed HB harvesting in extracting viable seed.

Swathing subterranean clover is a viable alternative to HB harvesting, addressing efficiency and environmental concerns associated with the traditional method.

Keywords: geocarpic seeds, harvest efficiency, mechanical swath, novel harvesting technology, peanut digger, seed harvesting, seed loss, seed quality, sub clover, subterranean clover, windrowing.

Introduction

Subterranean clover (Trifolium subterraneum) is southern Australia’s most widely sown annual pasture legume. It is valued for its dual role as a nutritious livestock feed and a biological nitrogen fixer, benefitting other pasture components and crops grown in rotation (Nichols et al. 2012; Roy et al. 2020). Subterranean clover’s popularity is further attributed to its geocarpic nature, with many of its seed-containing burrs buried shallowly, particularly for T. subterraneumspp. subterraneum and yanninicum, protecting them from grazing animals and supporting pasture persistence (Smetham 2011; Nichols et al. 2013). However, this characteristic complicates seed harvesting, making it costly and labour-intensive (Hassall & Associates 2001; Moss et al. 2021a).

Conventional combine-harvesting techniques are unsuitable for subterranean clover due to its subterranean burrs (Moss et al. 2022a). The most common harvesting approach uses the Horwood-Bagshaw Clover Harvester (HB), a specialised suction harvester first commercially produced in 1962, which remains the industry standard despite the cessation of its manufacture in the early 1990s (Moss et al. 2021a). This method requires multiple tillage passes to unearth burrs, with a median of six tillage and raking passes needed before vacuum harvesting (Moss et al. 2021a). While effective, these practices cause significant soil disturbance, degrade soil structure, and remove surface residues essential for erosion control, contributing to nutrient loss and adverse environmental impacts (Blanco-Canqui and Ruis 2018; Otwani 2020; Moss et al. 2021a). The process also generates large quantities of dust, which affect air quality and raise concerns about the industry’s environmental sustainability. With its high labour and operational costs, this outdated technology threatens the viability of subterranean clover seed production and pasture renovation in southern Australia.

Swathing is a common agricultural practice for indeterminate crops prone to seed shedding (Dodds and Dew 1958; Dodds 1959, 1961; May et al. 2005; Vera et al. 2007; Sorensen et al. 2015). It involves cutting crops before full senescence, forming windrows for drying and seed maturation, and then collecting and threshing the swaths to recover the seed. Compared to the median total of 11 machinery operations required to achieve clean seed in the current subterranean clover harvesting process (Moss et al. 2021a), typical swathing-based harvest approaches require only two machinery passes, significantly reducing time, labour, and soil disturbance.

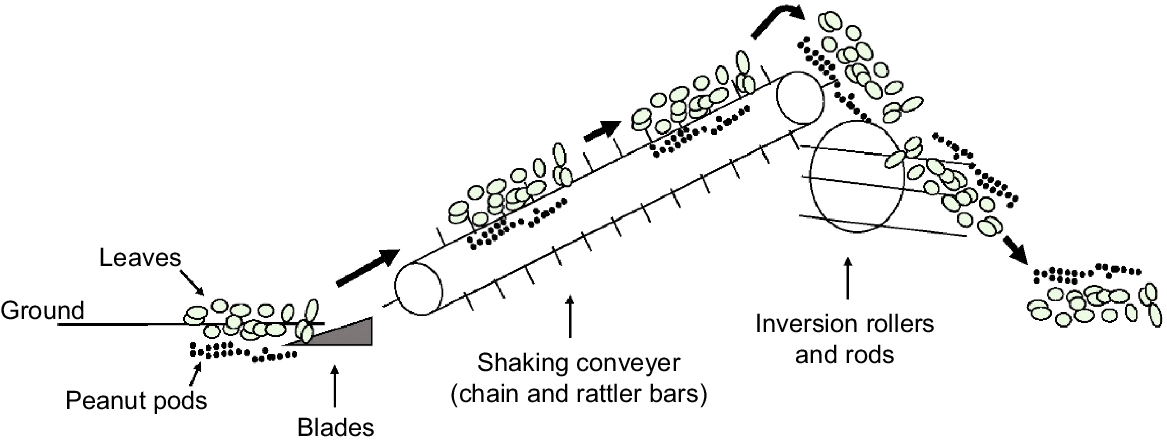

Peanut (Arachis hypogaea) is another geocarpic legume that is cultivated in rows typically spaced about 900 mm apart (de Almeida Moreira et al. 2024). Its pods develop up to 10 cm below the soil surface (Rachaputi et al. 2021) and are harvested using a two-stage swathing technique. The initial step, referred to as ‘digging’, involves use of a peanut digger (Fig. 1a) when 60–80% of pods have reached maturity as determined by pod mesocarp colour (Williams and Drexler 1981; Wright et al. 2015). The digger uses sharp, swept blades, each designed to sever one row of plant roots beneath the soil surface (Bader and Sumner 2009; Kelley Manufacturing Company 2015). After cutting, the plants with pods attached are lifted onto a conveyor system equipped with rattler bars that dislodge soil from the roots. The plants are then inverted and returned to the soil surface in windrows, with the roots and pods facing upwards. Due to the crop’s indeterminate growth habit, the digging stage may coincide with the later stages of flowering, and the pods can contain 40–50% moisture (Wright et al. 2015). Consequently, windrowed peanut plants are left to dry for 3–10 days before the second harvesting step: collection and processing by a peanut combine (Wright et al. 2015). Moss et al. (2022b) proposed peanut harvesting technology as a viable option for the subterranean clover seed industry, leveraging its commercial availability and scalability without necessitating costly development of specialised equipment.

Schematic diagram of peanut digger swathing operation, with main components labelled and the flow of peanut material indicated by large arrows.

Preliminary trials indicate that peanut diggers show promise for swathing subterranean clover, but success depends on plant senescence levels (Moss et al. 2022b). Adequate moisture content in stems and peduncles ensures burrs remain attached during lifting and inversion, whereas advanced senescence increases brittleness and burr loss (Moss et al. 2021b, 2022b). In annual plants like subterranean clover, whole-plant senescence and seed development are closely linked, as senescence remobilises nutrients from vegetative to reproductive structures (Noodén et al. 2004; Masclaux-Daubresse et al. 2008; Guiboileau et al. 2010). Consequently, less senesced plants may bear less mature seeds. For many crops, seed yield and quality improve during development, with individual seed weight and proportion of germinable seeds (including hard seeds) both increasing over time (Dodds and Dew 1958; Dodds 1959, 1961; Collins and Quinlivan 1980; Mouwen 1983; Elias and Copeland 2001; May et al. 2005; Vera et al. 2007; Menendez et al. 2019; Ahmed et al. 2025). In some cases, seed quality can continue to improve even after maximum seed yield is reached (Elias and Copeland 2001; May et al. 2005). Given the opposing dynamics of plant senescence and seed development, timing appears critical for successful subterranean clover swathing. Moreover, since conventional subterranean clover seed harvesting occurs well after plant senescence and drying, whereas swathing occurs beforehand, a comparative analysis of seed quality parameters using both methods is warranted.

This study evaluates, at two stages of crop development, a modified peanut digger for swathing subterranean clover as the first step of a potential two-stage harvest process, comparing efficiency, yield and seed quality with conventional HB harvesting. The aim was to determine the feasibility and potential benefits or limitations of a swathing-based approach for the subterranean clover seed industry.

Materials and methods

Experimental site

The experiment was conducted at Bell Pasture Seeds in Capel, Western Australia (WA) (33.55950°S, 115.66318°E) with three times of harvest treatments: (1) swathing on 25 November 2022; (2) swathing on 1 December 2022; and (3) harvest on 14 February 2023. The site had negligible slope. There was some east-west variation in vegetative growth prior to commencement of the trial. Rainfall and temperature data for the growing season and testing period, sourced from the Department of Primary Industries and Regional Development’s (2024) local weather station, are presented in Table 1. The trial site was characterised as a grey deep sandy duplex soil (Department of Primary Industries and Regional Development 2022). Soil samples (0–10 cm) were collected from four equally spaced locations within the trial area and analysed by CSBP Analytical Laboratories (Bibra Lake, WA) following methods described by Rayment and Lyons (2011) and a mid-infrared particle size analysis method. The soil comprised 84.97% sand, 9.38% clay, and 5.65% silt, with a pH in CaCl2 of 5.6. Nutrient analyses revealed 20 mg kg−1 nitrate-nitrogen, 15 mg kg−1 ammonium-nitrogen, and 3.64% organic carbon. Soil gravimetric water content measured 12% on 25 November 2022, 6% on 1 December 2022 and 2% on 14 February 2023. The trial paddock comprised a rainfed crop of Trifolium subterraneum L. spp. yanninicum cv. Trikkala, with strong burr burial, that had been grazed by cattle every 4–6 weeks from germination until flowering. On 24 November 2022, the site was cut and baled for hay, which removed approximately 2 t ha−1 of shoot matter and left an equivalent plant dry weight in the field during the swathing trial.

| 2022 | 2023 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mar | Apr | May | Jun | Jul | Aug | Sep | Oct | Nov | Dec | Jan | Feb | ||

| Min. temp | 14.8 | 10.4 | 7.7 | 8.1 | 6.0 | 5.6 | 7.1 | 6.1 | 8.7 | 12.4 | 14.1 | 14.3 | |

| Max. temp | 28.6 | 24.5 | 20.8 | 17.5 | 17.4 | 17.0 | 19.5 | 20.4 | 24.9 | 29.4 | 32.2 | 32.3 | |

| Rainfall | 4.6 | 44.0 | 105.6 | 103.8 | 169.0 | 121.4 | 69.4 | 29.0 | 18.0 | 1.2 | 0.8 | 0 | |

Equipment

Hay cutting and baling involved a New Holland H8060 Speedrower self-propelled windrower and a New Holland BigBaler 1290 PLUS. The swathing treatment involved a modified two-row Kelly Manufacturing Co peanut digger-shaker-inverter (Fig. 1, 1.5 m operational width, operating at ~3 km h−1) followed by hand sampling to collect and thresh windrowed burrs. Based on initial evaluations by Moss et al. (2022b), minor modifications and adjustments were made to enhance the peanut digger’s performance for subterranean clover. The conventional harvesting treatment used a 1989 J series HB harvester with a standard 1.22 m pickup duct, operated at ~2 km h−1, following one pass with a Breviglieri Mekfarmer 220 power harrow set at 2.5 cm depth (operated by a Case IH Puma 210 tractor) and two passes with a dragged chain link harrow, for a total of four machinery passes. The HB harvest treatment followed typical commercial production practices for the seed producer, which involved fewer total machinery passes than many other seed growers in the survey of Moss et al. (2021a). For each separate test, the peanut digger and HB were both coupled to the same New Holland Ford 7840 tractor.

Experimental design

Three treatments were evaluated: (1) swathing with a modified peanut digger on 25 November 2022 (early stages of senescence) followed by hand collection of seeds; (2) swathing with a modified peanut digger on 1 December 2022 (mostly senesced plants) followed by hand collection of seeds; (3) conventional HB harvesting (single pass) on 14 February 2023, following three passes of preparatory tillage as described above. Each treatment was applied to 75 m long plots. Plot widths corresponded to two treatment widths: (1) 1.5 m for swathing; and (2) 1.22 m for the HB. Four replicate blocks were positioned from west to east, with one plot of each treatment randomly arranged in each block.

Pre- and post-harvest quadrat sampling

Five quadrats (1.48 m × 0.2 m) were placed equidistantly along each plot 1 day before each harvest to collect pre-harvest plant and soil data. For the HB treatment, pre-harvest sampling occurred after preparatory machinery operations. Pre-harvest measurements included senescence rating, greenness index, shoot biomass and potential seed yield. Adjacent soil gravimetric water content was also recorded.

Senescence within quadrats was rated on a scale of 1 (no senescence) to 5 (complete senescence; Table 2). Quadrats were imaged from a height of 1 m using an iPhone 13 (Apple Inc., USA). Average values of red, green and blue within each quadrat were determined using Fiji (ImageJ, ver. 1.54k; Schindelin et al. 2012). The greenness index (Gi) was calculated using the formula from Yuan et al. (2016):

where G, R, and B are green, red, and blue intensities (0–255).

| Rating | Senescence | Leaf, stem, and peduncle conditions | |

|---|---|---|---|

| 1 | Nil | Lush green leaves, peduncles and stems | |

| 2 | Early | Some leaf yellowing; green peduncles and stems | |

| 3 | Moderate | Most leaves yellow with some dead; yellow/green peduncles and stems | |

| 4 | Advanced | Most leaves dead; yellow/green peduncles and stems with some sap | |

| 5 | Full | All leaves, peduncles and stems dead, with no sap |

One day before swathing on 25 November and 1 December 2022, aboveground plant material in each quadrat was cut to ground level using electric clippers, oven-dried at 40°C for 1 week, and weighed after removing non-subterranean clover material to determine post-hay shoot dry weight. Soil cores (0–10 cm depth) were taken adjacent to quadrats, weighed, oven-dried at 105°C for 3 days and re-weighed to determine soil gravimetric water content. Soil cores were taken for every quadrat in the swathing treatments, but only two of five quadrats per plot in the HB treatment.

Following each harvest or swathing operation, post-harvest quadrats were positioned adjacent to pre-harvest quadrats to measure seed remaining after harvest. Pre- and post-harvest soil and plant material were collected to a depth of 30 mm within each quadrat. All burrs were collected following sieving (3.3–3.5 mm mesh) to remove soil, threshed, cleaned to remove debris, and weighed. Pre-harvest seed samples represented potential pre-harvest seed yield, while post-harvest samples represented seed left in the ground following the harvest operation. Seed extraction efficiency (SEE), which is the proportion of seed extracted from the ground by swathing or harvesting as a proportion of all available pre-harvest seed, was calculated as:

where Savailable is pre-harvest seed weight and Sleft is post-harvest seed weight.

Post-harvest seed analysis

Windrowed burr samples were collected by hand after swathing from five equidistant quadrats (20 cm × 20 cm) within each plot. Samples were collected on 1 December (6 days post-swathing) and 9 December (14 days post-swathing) for the 25 November swathing treatment and 9 December (8 days post-swathing) for the 1 December swathing treatment to allow swathed burrs to mature and dry in the field. Burr samples were stored initially in an oven at 40°C for 1 week then sieved, threshed and cleaned to obtain seed samples, resulting in five post-harvest seed samples per plot. For the HB operation, burrs were threshed and partially cleaned in the machine, with all seed collected from the seed bin. The seed harvested from each HB plot was collected as a single sample, where five random subsamples of approximately 100 g each were obtained. Seed samples were stored in sealed containers at room temperature until analysis.

In June 2023, 10 subsets of 10 seeds were randomly selected from each post-harvest seed sample, oven-dried at 40°C for at least 24 h and weighed to determine mean seed dry weight. These seeds were scarified to overcome hardseededness using 14 s of compressed air in a small brass cylinder coated with fine sandpaper (FlexOvit FL250P – P240), as described by Nichols et al. (2009). Scarified seeds were placed in Petri dishes containing moist Whatman No. 3 filter paper and kept in a temperature-controlled cabinet at 15°C for 14 days. Three, seven, and 14 days after commencement, seeds with emerged radicals and no visible physical deformities or irregularities were considered germinated, according to the International Seed Testing Association standards. Germinated seeds were removed from the Petri dishes, and the germination percentage was calculated as the proportion of germinated seeds in each sample after 14 days. Seeds that had imbibed but remained ungerminated after 14 days were considered dormant.

Another 10 seeds were randomly selected from each post-harvest seed sample for a seedling vigour trial conducted in August 2024. Seeds were scarified as described above, except that swathed seeds were scarified for 15 s, while HB seeds were scarified for only 8 s, as they had already undergone some scarification during threshing by the HB. The scarified seeds were placed 1 cm deep in 15 cm diameter pots filled with sterilised commercial potting mix (Richgro, Jandakot, Western Australia). The mix was a blend of dark brown or black organic, granular material (pH 6.7) containing 89.1 mg L−1 nitrogen, <0.5 mg L−1 phosphorus and 235 mg L−1 potassium. Pots were inoculated with Group C rhizobia and kept in a well-lit glasshouse under irrigation, with a controlled 20°C/15°C day/night temperature regime for 21 days. Seedling emergence was recorded every 1–3 days, and after 21 days, the seedlings were counted and classified as: (1) healthy; (2) missing cotyledons (presumed due to over-scarification); or (3) stalled, where the seed coat had dried on the cotyledons and hindered growth. The number of fully expanded trifoliate leaves was counted for each healthy seedling to determine the development stage. Each seedling was then cut at the soil surface, and aboveground biomass was oven-dried at 70°C for 1 week before weighing.

SEE, germination percentage (Germ), and seedling emergence percentage (Em) were used to calculate viable yield efficiency (VYE) for each treatment, defined as the number of seeds extracted by a harvesting operation that germinated or emerged (depending on the methodology used) as a percentage of the potential pre-harvest seed yield. This value was calculated for both germination (VYEg) and seedling emergence (VYEe) as:

Statistical analysis

All statistical analyses were performed in RStudio (RStudio, Boston, MA, USA, ver. 4.3.3). Polynomial regression examined the relationship between the greenness index and senescence rating. Student’s t-tests compared the greenness index and senescence rating between two swathing treatments. Robust multiple linear regression assessed the effects of gravimetric water content, shoot dry weight, and swathing date on the greenness index. The effects of the greenness index on germination percentage and mean seed weight were analysed using quasibinomial logistic regression and linear regression, respectively. Analysis of variance evaluated the effects of harvest treatment, block and quadrat on mean seed weight, potential pre-harvest seed yield, average days to seedling emergence and individual seedling weight, while seed extraction efficiency, germination and dormancy percentage, and seedling emergence were analysed using beta, logistic and Poisson regressions, respectively. Post-hoc Sidak tests were performed when significant effects were found. Strip, box, and scatter plots were created to visualise results.

Results

Subterranean clover sward greenness during swathing

At the first swathing on 25 November, subterranean clover plants had begun to senesce (Fig. 2a), with a mean senescence rating of 2.98 and a mean greenness index of 0.362. By 1 December, senescence had noticeably advanced (Fig. 2b), with a mean senescence rating of 3.96 and a mean greenness index of 0.346, both significantly different from 25 November (P < 0.001). A strong relationship was observed between senescence rating and greenness index (adjusted R2 0.915, P < 0.001), described by the equation:

where Gi is the greenness index and SR is the senescence rating.

Images of harvesting operations: (a) swathing on 25 November 2022; (b) swathing on 1 December 2022; and (c) harvesting with a Horwood-Bagshaw clover harvester on 14 February 2023. Close-up images of burrs in windrows swathed on (d) 25 November and (e) 1 December. Note the visible change in pasture colour between (a) 25 November and (b) 1 December and the sward inversion, where green leaves are not visible as they are buried beneath soil-covered roots and burrs. Inverted windrows contained excessive soil – particularly on 25 November. This issue was later largely mitigated through further modification to the peanut digger.

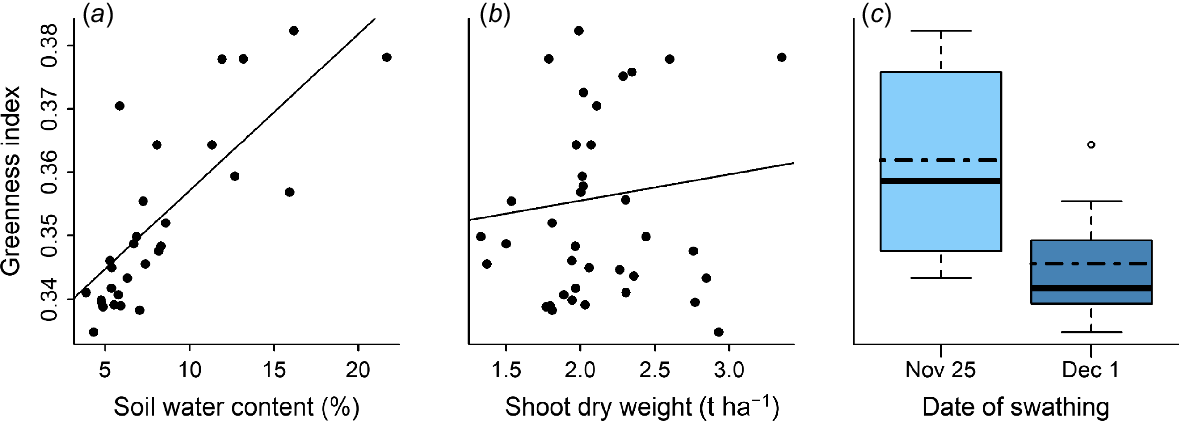

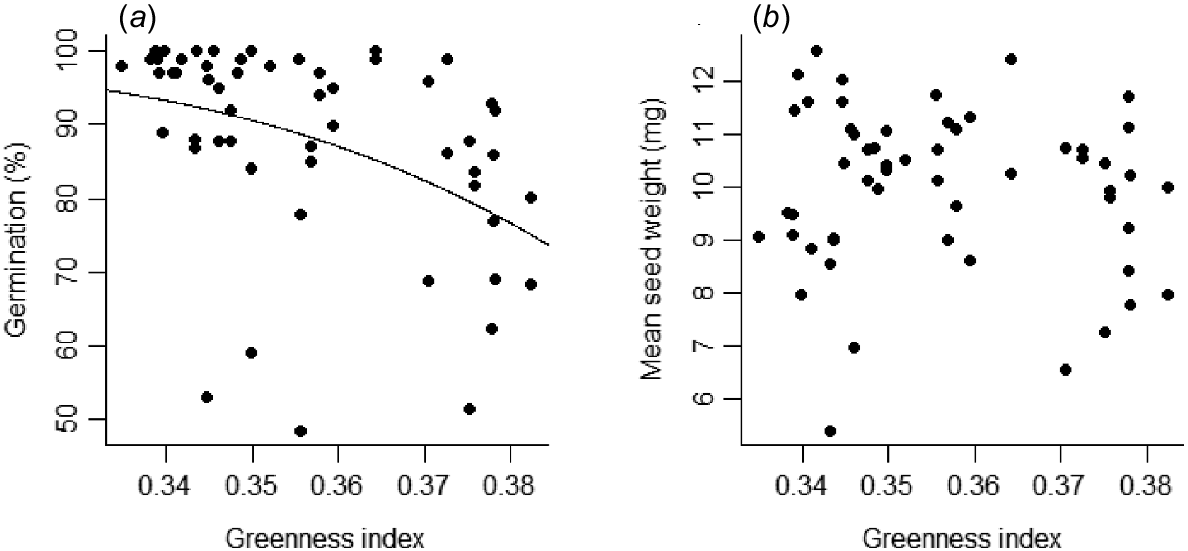

High variability across seed quality measurements, site baselining factors, and sward greenness during swathing treatments prompted an investigation into the relationship between these variables for individual quadrat samples. Gravimetric water content (P < 0.001), shoot dry weight at the time of trial (after hay cutting; P = 0.040) and swathing date (P = 0.030) all influenced the greenness index (adjusted R2 = 0.638; Fig. 3). Greenness index at the time of swathing significantly affected germination percentage (P = 0.003; Fig. 4a) but did not affect mean seed weight (P = 0.49; Fig. 4b).

Results from robust multiple linear regression (adjusted R2 = 0.6375) describing the effect of (a) gravimetric water content, (b) shoot dry weight during the trial (post hay cutting), and (c) swathing date on greenness index for the 25 November and 1 December swathing treatments. For (a) and (b), dots represent individual quadrats (n = 60). For (c), boxes represent the middle 50% of data points, with whiskers showing the lower and upper 25% of data points (n = 60). Extreme values are depicted as hollow circles, solid lines represent median values, and dashed lines represent mean values.

Effect of the greenness index on (a) germination percentage and (b) mean seed weight after swathing on 25 November and 1 December 2022. Dots represent individual quadrat values (n = 60). The quasibinomial regression model describing the relationship between germination percentage and the greenness index is indicated as a line.

Swather performance compared to commercial seed harvesting (HB

The modified peanut digger successfully cut subterranean clover swards below ground level and fed the plant material, with burrs attached, onto the conveyor (Fig. 2). Strong cohesiveness of the subterranean clover sods as they moved up the conveyor and over the inversion rollers resulted in excessive soil attached to the inverted rows. Weeds, including annual ryegrass (Lolium rigidum) and some other herbs, became tangled in the equipment and placed additional strain on the cutting blades, causing some flex and minor differences in cutting depth across their width. However, despite these issues, the peanut digger efficiently collected subterranean clover plants with burrs attached into windrows.

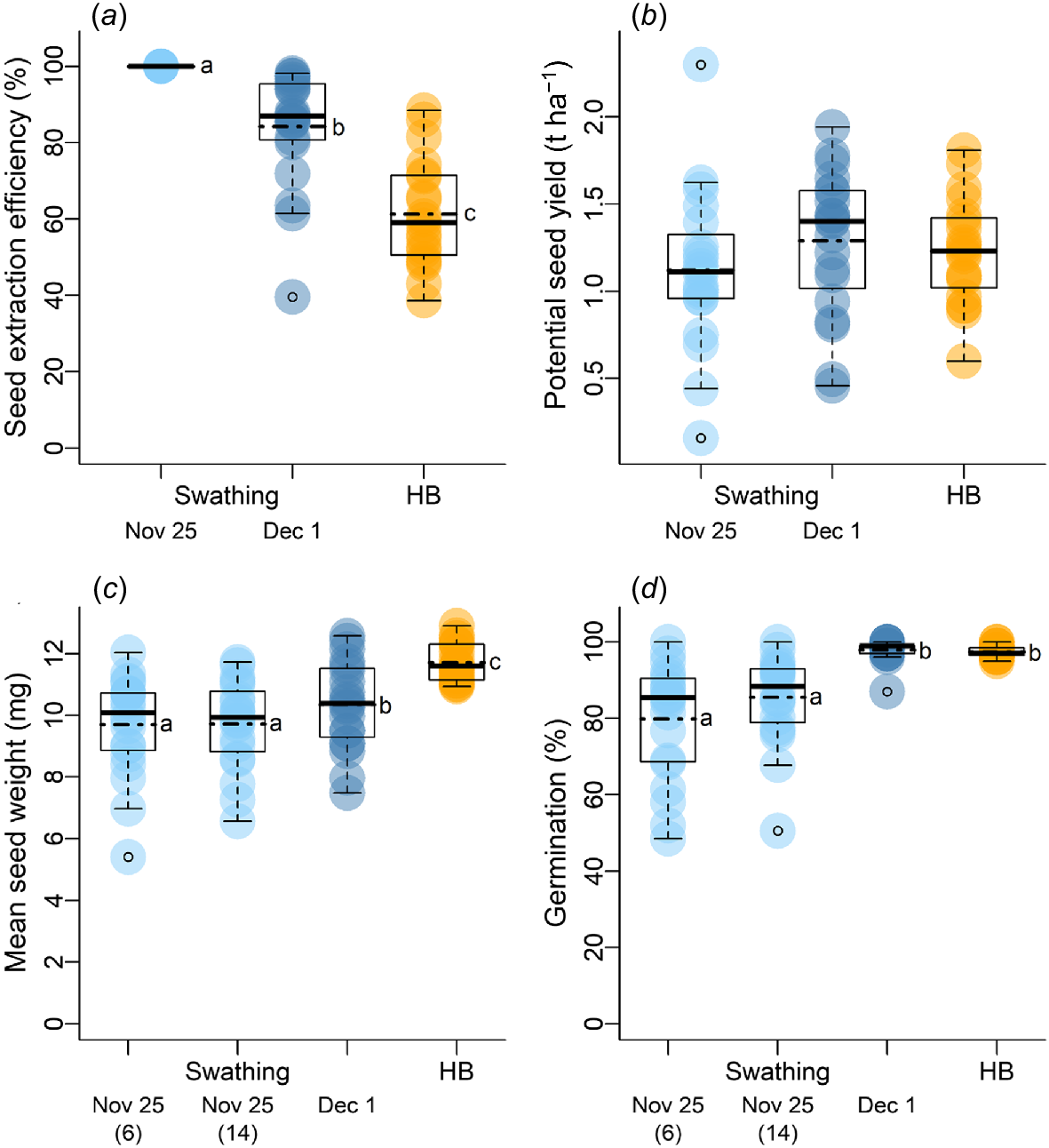

Seed extraction efficiency varied greatly among treatments (Fig. 5a, Table 3). Swathing on 25 November, when plants were still relatively green, resulted in nearly 100% seed extraction efficiency for this first harvesting step. Swathing on 1 December, when the sward had begun to senesce, resulted in a lower efficiency of 84.2%, but still higher than the HB harvesting treatment (61.3%). Seed extraction efficiency was unaffected by sample location (block or quadrat).

Effect of seed harvest treatment on (a) seed extraction efficiency, (b) potential pre-harvest seed yield, (c) mean seed weight, and (d) germination percentage. Treatments included swathing on 25 November 2022 (samples collected from windrows 6 or 14 days later), swathing on 1 December 2022 (samples collected 8 days later), and Horwood-Bagshaw harvesting on 14 February 2023. Each solid circle represents a quadrat sample (n = 20) or subsample for mean seed weight (n = 200). The box represents the middle 50% of data points, and the whiskers the lower and upper 25% of data points; extreme values are shown as hollow circles. The solid and dashed lines represent the median and the mean, respectively. Statistical outcomes are in Table 3. Treatments annotated with the same letter have estimated marginal means that do not significantly differ at P = 0.05, according to post-hoc analyses.

| Treatment | Block (east–west) | Quadrat (north–south) | ||

|---|---|---|---|---|

| Seed extraction efficiency | <0.001*** | 0.055 | 0.340 | |

| Potential yield | 0.412 | 0.567 | 0.582 | |

| Mean seed weight | <0.001*** | <0.001*** | 0.058 | |

| Germination percentage | <0.001*** | 0.636 | 0.571 | |

| Total seedling emergence | <0.001*** | 0.931 | 0.551 | |

| Average days to emergence | 0.308 | 0.510 | 0.733 | |

| Individual seedling weight | 0.003** | 0.200 | 0.663 | |

| Viable yield efficiency for germination | <0.001*** | 0.042* | 0.283 | |

| Viable yield efficiency for emergence | <0.001*** | 0.161 | 0.064 |

See Methods for the analysis used. There were three treatments for seed extraction efficiency and potential yield (swathing 25 November 2022, swathing 1 December 2022, and Horwood-Bagshaw (HB) harvesting) and four treatments for all other variables (swathing 25 November 2022 with collection 6 or 14 days later, swathing 1 December 2022, and HB harvesting), with five quadrat samples collected from each of four blocks for each treatment.

*P < 0.005; **P < 0.01; ***P < 0.001.

Seed yield and quality

Potential pre-harvest seed yield did not differ among treatments (Fig. 5b, Table 3), indicating that seed yield was not affected by the earlier removal date of swathing compared to conventional seed harvesting. The potential pre-harvest seed yield was unaffected by sample location (block or quadrat).

Both mean seed weight and germination percentage varied among treatments (Table 3). Collection time following 25 November swathing (6 or 14 days post-swathing) did not affect mean seed weight (Fig. 5c, both 9.7 mg), which was lighter than windrows swathed on 1 December (10.3 mg). Seeds from both swathing dates were lighter than seeds collected from the HB seed bin (11.7 mg). Mean germination percentage (Fig. 5d) did not differ between collection times following the 25 November swathing treatment (80.5% and 86.9% collected 6 and 14 days after swathing, respectively), but was lower and more variable than other treatments. Germination percentage was higher for seeds swathed on 1 December (98.0%), which did not differ from the HB treatment (97.5%). Germination percentage was unaffected by sample location (block or quadrat), while block significantly affected mean seed weight. Seed dormancy varied among treatments (P < 0.001) but was unaffected by sample location (block P = 0.16 or quadrat P = 0.46). Seed dormancy did not differ between collection times following swathing on 25 November (2.6% and 1.7% collected 6 and 14 days after swathing, respectively), but was significantly lower for samples swathed on 1 December (0.5%) and harvested with an HB (0%).

Seedling vigour traits

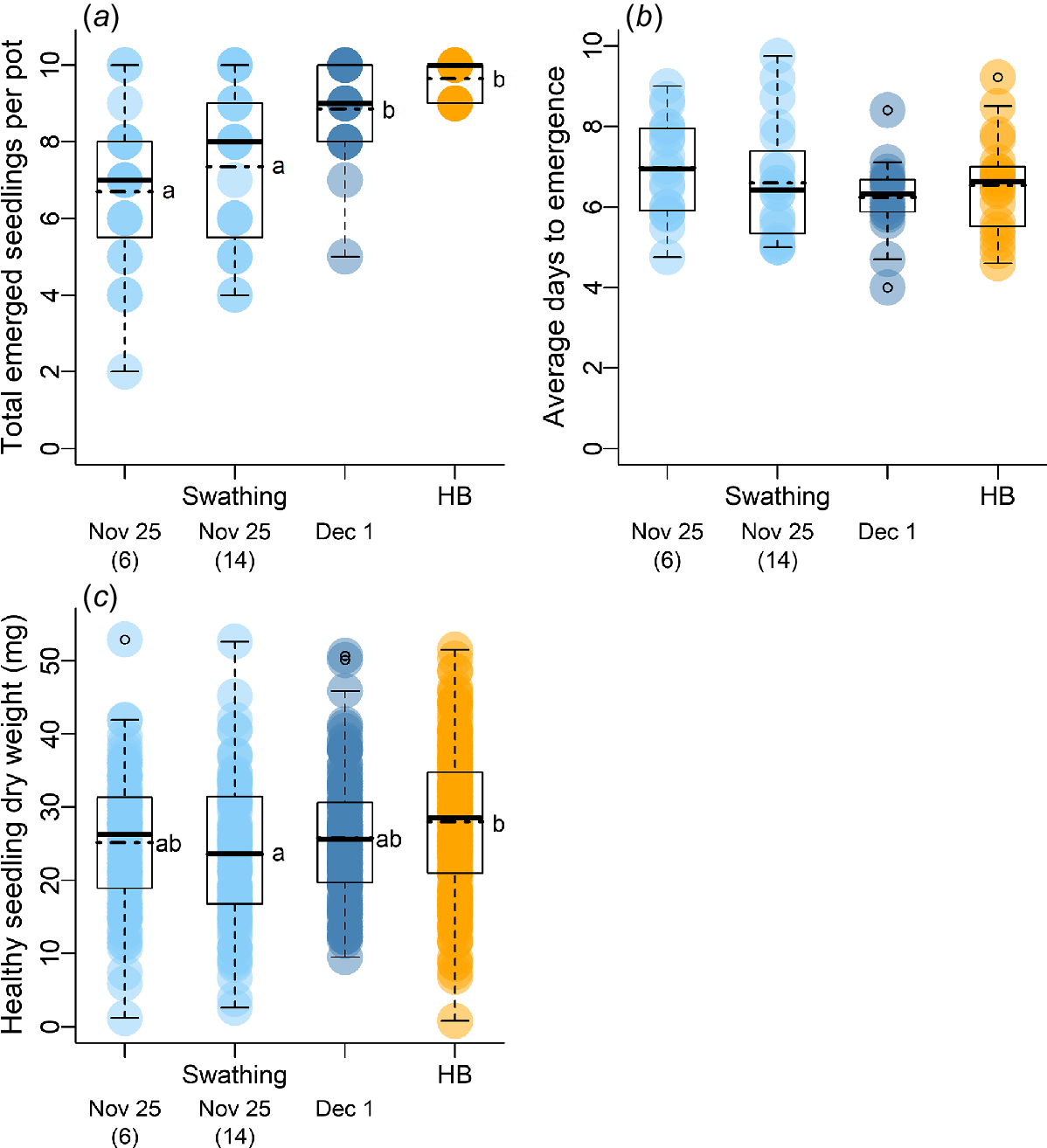

Seedling emergence was lowest for seeds swathed on 25 November (6.7 and 7.4 emerged seedlings out of a possible 10, collected 6 and 14 days after swathing, respectively; Fig. 6a). However, the mean emergence from seeds swathed on 1 December (8.9/10) did not differ from the HB treatment (9.7/10). Notably, the swathing treatments had greater variability among quadrats. Average days to emergence did not differ among treatments (Table 3, Fig. 6b). Most emergent seedlings were healthy, though some were missing cotyledons or had stalled development, which did not vary among treatments (P = 0.909 and 0.321, respectively) despite different scarification processes. Individual weights of healthy seedlings, excluding those with missing cotyledons or stalled development, were lower for seeds collected 14 days after swathing on 25 November than for the HB treatment, with no significant differences among other treatments (Table 3, Fig. 6c). The developmental stage of healthy seedlings did not vary among treatments (P = 0.45), with all treatments having an average of just under two fully expanded trifoliate leaves, corresponding to the V4 development stage of Teixeira et al. (2021).

Effect of seed harvest treatment on seedling vigour in a glasshouse trial. (a) Total seedling emergence per pot (of 10 seeds sown), (b) average days to emergence, and (c) individual weight of healthy seedlings 21 days after sowing (excluding those without cotyledons, stalled development, or had not emerged). Treatments included swathing on 25 November 2022 (samples collected from windrows 6 or 14 days later), swathing on 1 December 2022 (samples collected 8 days later), and Horwood-Bagshaw harvesting on 14 February 2023. See Fig. 5 for strip and box plot explanation (total emergence and average days to emergence n = 20; individual seedling weight 85 ≤ n ≤ 168). Statistical outcomes are in Table 3. Treatments annotated with the same letter have estimated marginal means that do not significantly differ at P = 0.05, according to post-hoc analyses.

Viable yield efficiency

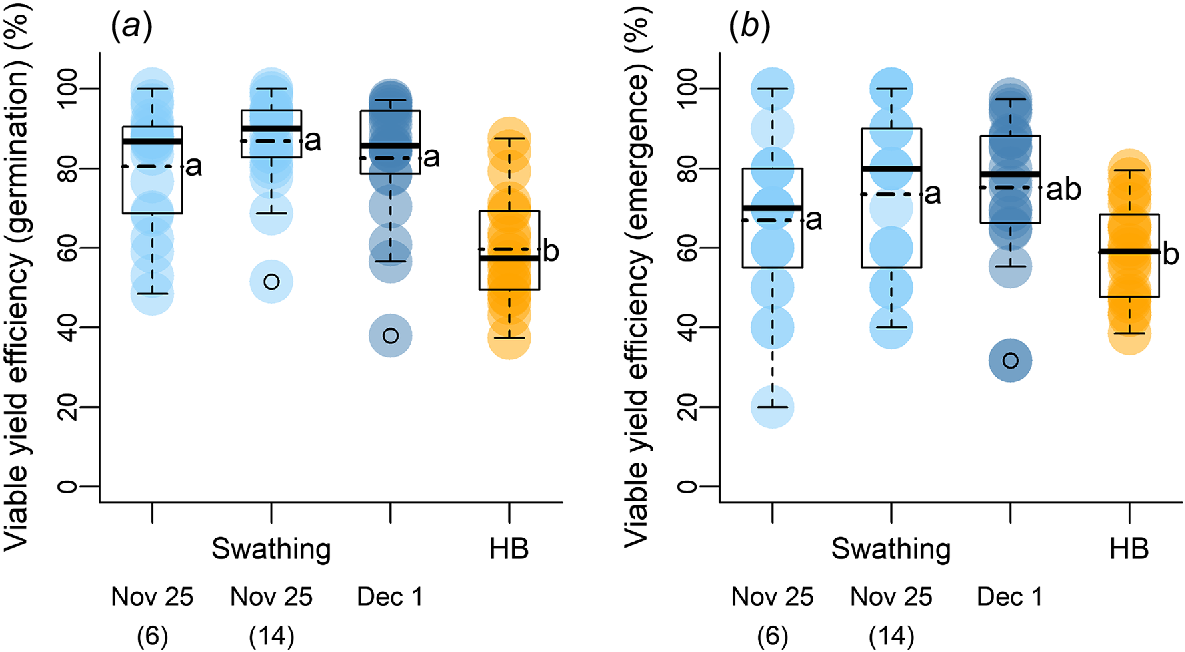

Viable yield efficiency, calculated from germination and seedling emergence data, varied with treatment (Table 3) but did not differ among swathing treatments (Fig. 7). Swathing on 25 November, as a first harvesting step, resulted in viable yield efficiency for germination of 80.5% and 86.9%, collected 6 and 14 days after swathing, respectively, and for emergence of 70.0% and 73.5%, collected 6 and 14 days after swathing, respectively. Both measures were higher than for the HB treatment (59.7% for gemination and 58.9% for emergence). While the viable yield efficiency for germination from swathing on 1 December as a first harvesting step (82.7%) was superior to that of the HB treatment, the viable yield efficiency for emergence from swathing on 1 December (75.2%) did not differ from the HB treatment. Block affected viable yield efficiency for germination but not for emergence. Neither of the variables were affected by quadrat location.

Effect of seed harvest treatment on (a) viable yield efficiency (germination), calculated from seed extraction efficiency and germination data, and (b) viable yield efficiency (emergence), calculated from seed extraction efficiency and seedling emergence data. Treatments included swathing on 25 November 2022 (samples collected from windrows 6 or 14 days later), swathing on 1 December 2022 (samples collected 8 days later), and Horwood-Bagshaw harvesting on 14 February 2023. See Fig. 5 for strip and box plot explanation (n = 20). Statistical outcomes are in Table 3. Treatments annotated with the same letter have estimated marginal means that do not significantly differ at P = 0.05, according to post-hoc analyses.

Discussion

The peanut digger successfully cut and windrowed plants in a commercial subterranean clover seed crop, demonstrating its suitability as a subterranean clover swathing technology. These findings align with the preliminary results of Moss et al. (2022b), which suggest that the peanut digger can serve as the first pass in a proposed two-step swathing and harvesting process for subterranean clover seed. Additionally, based on this single study, the peanut digger showed high seed extraction efficiency, collecting up to 100% of seeds into windrows (with early swathing) for collection and threshing with a second harvesting pass. Harvesting efficiency of an entire swathing and harvesting approach will likely be lower than this due to seed loss during the second pass where the swathed windrow is collected to remove seed. While this second pass was not examined in this study, the potential seed extraction efficiency of the swathed windrow compares favourably with the 61.3% efficiency of a single HB pass after three pre-harvest tillage operations. Conventional subterranean clover seed harvesting was found to involve a median of 11 passes, including six pre-harvest tillage passes and two HB passes (Moss et al. 2021a). While more HB passes could potentially increase seed extraction efficiency, they would significantly reduce time- and cost-effectiveness and increase the risk of soil degradation and erosion.

Conventional subterranean clover seed harvesting occurs after full plant senescence, when seed yield and quality are presumed to peak. However, swathing takes place before full senescence, leaving uncertainty about the yield and seed quality at this stage. In this study, potential seed yield did not vary across treatments, indicating that maximum seed yield was likely reached before moderate senescence occurred. However, several seed quality measures changed over time, consistent with the findings of Elias and Copeland (2001) and May et al. (2005), who observed that seed quality for canola (Brassica napus) and oats (Avena sativa) may improve even after maximum yield is achieved. Mean seed weight increased over time, with seeds swathed on 25 November 2022 being the lightest, followed by those swathed on 1 December 2022, and finally those harvested by the HB in February 2023. This finding is in line with studies by Collins and Quinlivan (1980), Mouwen (1983) and Ahmed et al. (2025), which showed that seed weight increases with maturity. It is worth noting that the mean seed weight observed in the HB treatment may have been artificially inflated due to the machine’s internal threshing and cleaning process that can remove lighter seeds. Indeed, Moss (2022) found mean subterranean clover seed weight collected by the HB was higher than the actual pre-harvest seed weight in the field, most likely due to ejection of smaller seeds in the HB threshing and cleaning process. Thus, it is uncertain whether seed weight genuinely increased from December to February.

Seed viability also increased over time in this trial. Seeds swathed on 25 November exhibited lower and more variable germination and seedling emergence than seed swathed or HB-harvested later, supporting findings by Collins and Quinlivan (1980), Mouwen (1983) and Ahmed et al. (2025), where it was found that germination percentage tends to increase during subterranean clover seed development. A small proportion of the difference in germinability may be attributed to the higher rates of seed dormancy among samples swathed on 25 November. However, no difference in viability was observed between seeds swathed on 1 December and those harvested by the HB in February, suggesting that maximum viability was reached by this second swathing date, when crop senescence was advanced. While germination and emergence rates followed similar trends across harvesting treatments, seedling emergence was slightly lower than germination for the swathing treatments, whereas the two measures were comparable for the HB treatment. This difference is likely due to the lower mean seed weight in the swathing treatments, as Black (1956) found that subterranean clover seed size influences hypocotyl elongation. Smaller seeds may struggle to emerge from depths that larger seeds can overcome. Despite this, no significant differences in seedling vigour were observed across treatments in terms of average days to emergence, seedling dry weight (one exception) or the number of trifoliate leaves 21 days after sowing. This contradicts the findings of Black (1956), but the discrepancy could be due to the failure of smaller seeds to emerge in our trial or a cultivar difference between Black (1956) and our study, although seed size ranges were similar.

Changes in plant senescence during effective swathing period

This study also highlighted the rapid changes in plant and seed characteristics during the effective swathing period. Plant senescence visibly advanced over the 6-day gap between the two swathing operations, significantly decreasing sward greenness. Declining rainfall, increasing temperatures and biomass removal for hay immediately before the trial may have accelerated senescence. Peduncle brittleness, linked to advanced senescence (Moss et al. 2021b, 2022b), likely contributed to the 16% decrease in seed extraction efficiency between the swathings on 25 November and 1 December. Mean seed weight, germination percentage, and seedling emergence increased as senescence progressed. Notably, there was significant variability in plant senescence or greenness across the field during both swathing dates. Swathing date, soil water content, and shoot dry weight accounted for 63.8% of the variability in sward greenness across the trial site. Plants were less green in areas with lower soil moisture as water deficit stress accelerated leaf senescence (Munné-Bosch and Alegre 2004). Conversely, areas with greater shoot biomass remained greener or less senesced. The relationship between shoot dry weight and sward greenness is complex, as the underlying cause of dry weight variability remains unclear. However, it can be speculated that areas with greater shoot dry weight experienced more favourable growing conditions, such as improved soil water retention, which facilitated stronger root growth, increasing the plant’s resilience to water stress and decreasing overall environmental stress at the end of the growing season. Reduced subterranean clover plant dry weight in certain areas may indicate a greater weed burden, with competition for water causing an earlier onset of senescence. Since both senescence and seed quality tend to increase over time, it is plausible that a relationship exists between them. While sward greenness did not influence mean seed weight, decreased plant greenness was associated with higher seed germination, suggesting that advanced plant senescence may have caused the abortion of younger, more immature seeds that would otherwise reduce germination percentage, which is a process that can occur naturally during senescence, especially under water deficit conditions (Smith et al. 1998).

Potential of a swathing approach as an alternative subterranean clover seed harvesting method

The results of this trial demonstrate that effective swathing, as a first step for harvesting subterranean clover, can be achieved without adversely affecting potential yield. While earlier swathing resulted in a lower proportion of viable seeds, the emerging seeds produced comparable seedling vigour to those from later swathing or conventional harvesting. Furthermore, the increased seed extraction efficiency may outweigh any reductions in seed germination and emergence caused by earlier swathing. Viable yield efficiency did not differ among swathing treatments despite variations in seed extraction efficiency, germination and seedling emergence. This finding suggests a window exists when the trade-offs between swathing efficiency and seed quality allow for effective and efficient swathing. However, the rapid changes in plant and seed characteristics imply that viable yield efficiency may drop significantly outside this window. Furthermore, the duration of this window may vary significantly in response to climatic conditions and among subterranean clover cultivars. Further research into the relationships between plant senescence and seed development would be valuable for optimising swathing procedures.

This study presents results from one testing season at a single site and for one subterranean clover cultivar from T. subterraneum spp. yanninicum. Further research will determine its applicability for harvesting subterranean clover T. subterraneum spp. subterraneum and brachycalycinum as well as the regions and situations where a swathing approach will be viable. In particular, soil structure is likely to impact seed loss and swathing efficiency, with heavier soils likely to be more problematic. Additionally, this study focusses only on the first swathing step of what would be a two-stage harvest operation. Future research needs to explore stage two; that is, the mechanisation of the swath harvesting to recover the seed using combine harvester or other approaches, which will likely be less technologically challenging than the removal of burrs from the soil. Nonetheless, under the conditions of this trial, it was demonstrated that a swathing approach can achieve comparable or superior harvesting efficiency compared to the current subterranean clover industry standard, with fewer machinery operations. Hence, swathing subterranean clover would likely help mitigate soil degradation and erosion, as it could replace an average of six conventional tillage passes with a single less-destructive non-inversion tillage pass (Crittenden et al. 2015). The subsequent harvesting of swathed windrows with one pass of a conventional combine instead of a median of two suction-based HB passes produces less dust during harvesting and reduces soil nutrient removal (Otwani 2020; Moss et al. 2021a). As swathing is a widely adopted agricultural practice, adoption of commercially available swathing equipment for subterranean clover seed harvesting, although requiring some modification, would allow the industry to benefit from technological advancements in larger agricultural sectors. This study has demonstrated that swathing subterranean clover is viable and can deliver reduced soil disturbance and technological sustainability compared to the HB. We therefore conclude that a swathing-based harvesting approach presents a promising alternative to current subterranean clover seed harvesting practices.

Glossary

| Burr | The false fruit of subterranean clover, covered in hooks or teeth, containing 3–5 pods, each with a single seed. |

| Geocarpy | The production or ripening of fruits and seeds belowground. |

| Hardseededness | A form of physical dormancy where the seed coat remains impermeable, preventing imbibition and germination, even under favourable temperature and moisture conditions. |

| Indeterminate | Refers to plants that continue to grow, flower and produce seed until growth is halted by external factors rather than by developing a terminal inflorescence. |

| Peduncle | The stalk on a plant that bears an inflorescence. |

| Seed extraction efficiency | The proportion of subterranean clover seed removed from the ground during harvesting operations, expressed as a percentage of the total pre-harvest seed available. |

| Senescence | The final developmental stage of an annual plant before death, when vegetative organs undergo a regulated breakdown of cellular structures, with nutrients remobilised to reproductive organs. |

| Swathing | An agricultural practice where crops are cut before full senescence and arranged into windrows to complete maturation in preparation for harvest. |

| Viable yield efficiency | The proportion of seeds extracted during the harvesting operation that germinate and/or emerge (depending on the methodology used) – and thus are considered viable – expressed as a percentage of the total potential pre-harvest seed yield. |

Data availability

The data that support this study are available in the University of Western Australia Research Repository at doi:10.26182/8jdp-qq18.

Conflicts of interest

Megan Ryan is an Associate Editor of Crop & Pasture Science but was not involved in the peer review or any decision-making process for this manuscript. The authors declare no other conflicts of interest.

Declaration of funding

The authors acknowledge AgriFutures Australia Pasture Seeds for funding this research as part of the project ‘Building new technologies for sustainable and profitable sub clover seed harvesting’ (PRO-015149). The peanut digger used in this study was purchased with assistance from the A.W. Howard Memorial Trust. RW acknowledges the financial support of the Research Training Program Stipend and A.W. Howard Memorial Trust Postgraduate Research Fellowship.

Acknowledgements

We thank Rob Bell at Bell Pasture Seeds, Capel, WA, for allowing us to conduct this trial on his seed crop and providing us with equipment and personnel to perform machinery operations. We thank Rodney Rogers for the use of his Horwood-Bagshaw clover harvester. We acknowledge the help of several UWA casual staff members who assisted in sample collection and processing. We acknowledge proof reading and editing by Tweak Editing.

References

Ahmed S, Singh P, Middleton J, Merritt D, Jenkins S, Nichols P (2025) Impact of seed maturation on the morphology, nutrition, microbiome composition and germinability of subterranean clover (Trifolium subterraneum) seeds. Grass and Forage Science [In press].

| Google Scholar |

Black JN (1956) The influence of seed size and depth of sowing on pre-emergence and early vegetative growth of subterranean clover (Trifolium subterraneum L.). Australian Journal of Agricultural Research 7, 98-109.

| Crossref | Google Scholar |

Blanco-Canqui H, Ruis SJ (2018) No-tillage and soil physical environment. Geoderma 326, 164-200.

| Crossref | Google Scholar |

Collins WJ, Quinlivan BJ (1980) The effects of a continued water supply during and beyond seed development on seed production and losses in subterranean clover swards. Australian Journal of Agricultural Research 31, 287-295.

| Crossref | Google Scholar |

Crittenden SJ, Poot N, Heinen M, van Balen DJM, Pulleman MM (2015) Soil physical quality in contrasting tillage systems in organic and conventional farming. Soil and Tillage Research 154, 136-144.

| Crossref | Google Scholar |

Department of Primary Industries and Regional Development (2022) Soil landscape mapping - Western Australia attributed by WA Soil Group (DPIRD-076). Available at https://public-services.slip.wa.gov.au/public/rest/services/SLIP_Public_Services/Soil_Landscape/MapServer/26 [accessed 7 November 2024]

Department of Primary Industries and Regional Development (2024) DPIRD weather stations: Floreat Park. Available at https://weather.agric.wa.gov.au/station/FL [accessed 30 August 2024]

Dodds ME (1959) The effect of swathing at different stages of maturity on the bushel weight and yield of fall rye. Canadian Journal of Plant Science 39, 477-482.

| Crossref | Google Scholar |

Dodds ME (1961) The effect of swathing at different stages of maturity on the bushel weight and yield of oats. Canadian Journal of Plant Science 41, 401-406.

| Crossref | Google Scholar |

Dodds ME, Dew DA (1958) The effect of swathing at different stages of maturity upon the bushel weight and yield of barley. Canadian Journal of Plant Science 38, 495-504.

| Crossref | Google Scholar |

Elias SG, Copeland LO (2001) Physiological and harvest maturity of canola in relation to seed quality. Agronomy Journal 93, 1054-1058.

| Crossref | Google Scholar |

Guiboileau A, Sormani R, Meyer C, Masclaux-Daubresse C (2010) Senescence and death of plant organs: nutrient recycling and developmental regulation. Comptes Rendus. Biologies 333, 382-391.

| Crossref | Google Scholar | PubMed |

Kelley Manufacturing Company (2015) 2, 4, 6 & 8 row peanut digger-shaker-inverter: operations manual. Available at https://www.kelleymfg.com/product/digger-shaker-inverter/ [accessed 23 November 2021]

Masclaux-Daubresse C, Reisdorf-Cren M, Orsel M (2008) Leaf nitrogen remobilisation for plant development and grain filling. Plant Biology 10, 23-36.

| Crossref | Google Scholar | PubMed |

May WE, Mohr RM, Lafond GP, Craig Stevenson F (2005) Oat quality and yield as affected by kernel moisture at swathing. Canadian Journal of Plant Science 85, 839-846.

| Crossref | Google Scholar |

Menendez YC, Botto JF, Gomez NV, Miralles DJ, Rondanini DP (2019) Physiological maturity as a function of seed and pod water concentration in spring rapeseed (Brassica napus L.). Field Crops Research 231, 1-9.

| Crossref | Google Scholar |

de Almeida Moreira BR, Marra TM, da Silva EA, de Brito Filho AL, Barbosa Júnior MR, dos Santos AF, da Silva RP, Vellidis G (2024) Advancements in peanut mechanization: implications for sustainable agriculture. Agricultural Systems 215, 103868.

| Crossref | Google Scholar |

Moss WM (2022) The development of novel approaches to sustainably harvest subterranean clover seed. PhD Thesis, The University of Western Australia, Crawley, WA, Australia. 10.26182/t769-hj24

Moss WM, Guzzomi AL, Foster KJ, Ryan MH, Nichols PGH (2021a) Harvesting subterranean clover seed-current practices, technology and issues. Crop & Pasture Science 72, 223-235.

| Crossref | Google Scholar |

Moss WM, Nichols PGH, Ryan MH, Foster KJ, Guzzomi AL (2021b) A chronology of subterranean clover burr detachment mechanics and implications for seed harvestability. Journal of The Royal Society Interface 18, 20210625.

| Crossref | Google Scholar |

Moss WM, Nichols PGH, Foster KJ, Ryan MH, Erskine W, Guzzomi AL (2022a) A century of subclover: Lessons for sustainable intensification from a historical review of innovations in subterranean clover seed production. In ‘Advances in agronomy. Vol. 171’. (Ed. DL Sparks) pp. 305–339. (Academic Press Inc.: Cambridge) 10.1016/bs.agron.2021.08.003

Moss WM, Nichols PGH, Foster KJ, Ryan MH, Guzzomi AL (2022b) Harvesting subterranean clover seed with peanut technology. In ‘System solutions for complex problems, Conference proceedings of the 20th Australian Agronomy Conference’, 18–22 September 2022, Toowoomba, Australia. (Eds L Bell, C Bhagirath) (Australian Society of Agronomy) Available at www.agronomyaustraliaproceedings.org

Munné-Bosch S, Alegre L (2004) Die and let live: leaf senescence contributes to plant survival under drought stress. Functional Plant Biology 31, 203-216.

| Crossref | Google Scholar | PubMed |

Nichols PGH, Cocks PS, Francis CM (2009) Evolution over 16 years in a bulk-hybrid population of subterranean clover (Trifolium subterraneum L.) at two contrasting sites in south-western Australia. Euphytica 169, 31-48.

| Crossref | Google Scholar |

Nichols PGH, Revell CK, Humphries AW, Howie JH, Hall EJ, Sandral GA, Ghamkhar K, Harris CA (2012) Temperate pasture legumes in Australia—their history, current use, and future prospects. Crop & Pasture Science 63, 691-725.

| Crossref | Google Scholar |

Nichols PGH, Foster KJ, Piano E, Pecetti L, Kaur P, Ghamkhar K, Collins WJ (2013) Genetic improvement of subterranean clover (Trifolium subterraneum L.). 1. Germplasm, traits and future prospects. Crop & Pasture Science 64, 312-346.

| Crossref | Google Scholar |

Noodén LD, Guiamét JJ, John I (2004) Whole plant senescence. In ‘Plant cell death processes’. (Ed. LD Noodén) pp. 227–244. (Academic Press Inc.: Cambridge) 10.1016/B978-012520915-1/50018-7

Rachaputi R, Chauhan YS, Wright GC (2021) Chapter 11 – Peanut. In ‘Crop physiology case histories for major crops’. (Eds VO Sadras, DF Calderini) pp. 360–382. (Academic Press Inc.: Cambridge) 10.1016/B978-0-12-819194-1.00011-6

Rayment GE, Lyons DJ (2011) ‘Soil chemical methods: Australasia.’ (CSIRO Publishing: Melbourne, Vic, Australia) 10.1071/9780643101364

Roy S, Liu W, Nandety RS, Crook A, Mysore KS, Pislariu CI, Frugoli J, Dickstein R, Udvardi MK (2020) Celebrating 20 years of genetic discoveries in legume nodulation and symbiotic nitrogen fixation. The Plant Cell 32, 15-41.

| Crossref | Google Scholar | PubMed |

Schindelin J, Arganda-Carreras I, Frise E, Kaynig V, Longair M, Pietzsch T, Preibisch S, Rueden C, Saalfeld S, Schmid B, Tinevez J-Y, White DJ, Hartenstein V, Eliceiri K, Tomancak P, Cardona A (2012) Fiji: an open-source platform for biological-image analysis. Nature Methods 9, 676-682.

| Crossref | Google Scholar | PubMed |

Smetham M (2011) The ecology and use of subterranean clover (Trifolium subterraneum) as a pasture legume. An Australasian perspective. Pastos 29, 5-63.

| Google Scholar |

Smith FP, Cocks PS, Ewing MA (1998) Seed production in cluster clover (Trifolium glomeratum L.). 1. Flowering time, abortion, seed size, and hardseededness along branches. Australian Journal of Agricultural Research 49, 961-964.

| Crossref | Google Scholar |

Sorensen RB, Lamb MC, Butts CL (2015) Can peg strength be used as a predictor for pod maturity and peanut yield? Peanut Science 42, 92-99.

| Crossref | Google Scholar |

Teixeira C, Hampton J, Moot D (2021) Phenological development of subterranean clover cultivars under contrasting environments. Annals of Applied Biology 179, 246-258.

| Crossref | Google Scholar |

Vera CL, Downey RK, Woods SM, Raney JP, McGregor DI, Elliott RH, Johnson EN (2007) Yield and quality of canola seed as affected by stage of maturity at swathing. Canadian Journal of Plant Science 87, 13-26.

| Crossref | Google Scholar |

Williams EJ, Drexler JS (1981) A non-destructive method for determining peanut pod maturity. Peanut Science 8, 134-141.

| Crossref | Google Scholar |

Yuan Y, Chen L, Li M, Wu N, Wan L, Wang S (2016) Diagnosis of nitrogen nutrition of rice based on image processing of visible light. In ‘2016 IEEE International Conference on Functional-Structural Plant Growth Modeling, Simulation, Visualization and Applications (FSPMA)’, pp. 228–232. (IEEE) 10.1109/FSPMA.2016.7818311